DIY Guns A Clear and Printed Danger

With open-sourced information, available materials, and a little bit of know-how, gun enthusiasts all over the world can make weapons in the privacy of their own homes. Some see this as an exercise in freedom and an expression of civil liberties, while others are concerned over issues of public safety.

Homemade firearms have been around for as long as guns have, but in this digital age, 3D-printed firearms have taken DIY to the next level. The technology behind homemade guns has not only become so advanced and sophisticated but it has also become extremely accessible as well, for as long as you know where to look.

Many gun enthusiasts in the United States, as well as Second Amendment advocates, see this as a cause for celebration, and protecting their rights to bear and keep arms fiercely. However, due to the rising cases of public shootings in the country, the call for tighter gun regulations continues to be a hotly debated topic. Compared to the rest of the globe, legislation for gun ownership and acquisition is very relaxed in the U.S.

(Also read: It’s a Bold New 3D Printed World)

3D printed Guns: A view to a kill

The advent of 3D printing in the early 2010s gave rise to next-level DIY creativity. Printing anything from shoes to scale models was now made possible for as long as one had access to a computer-aided design (CAD) file and polymers.

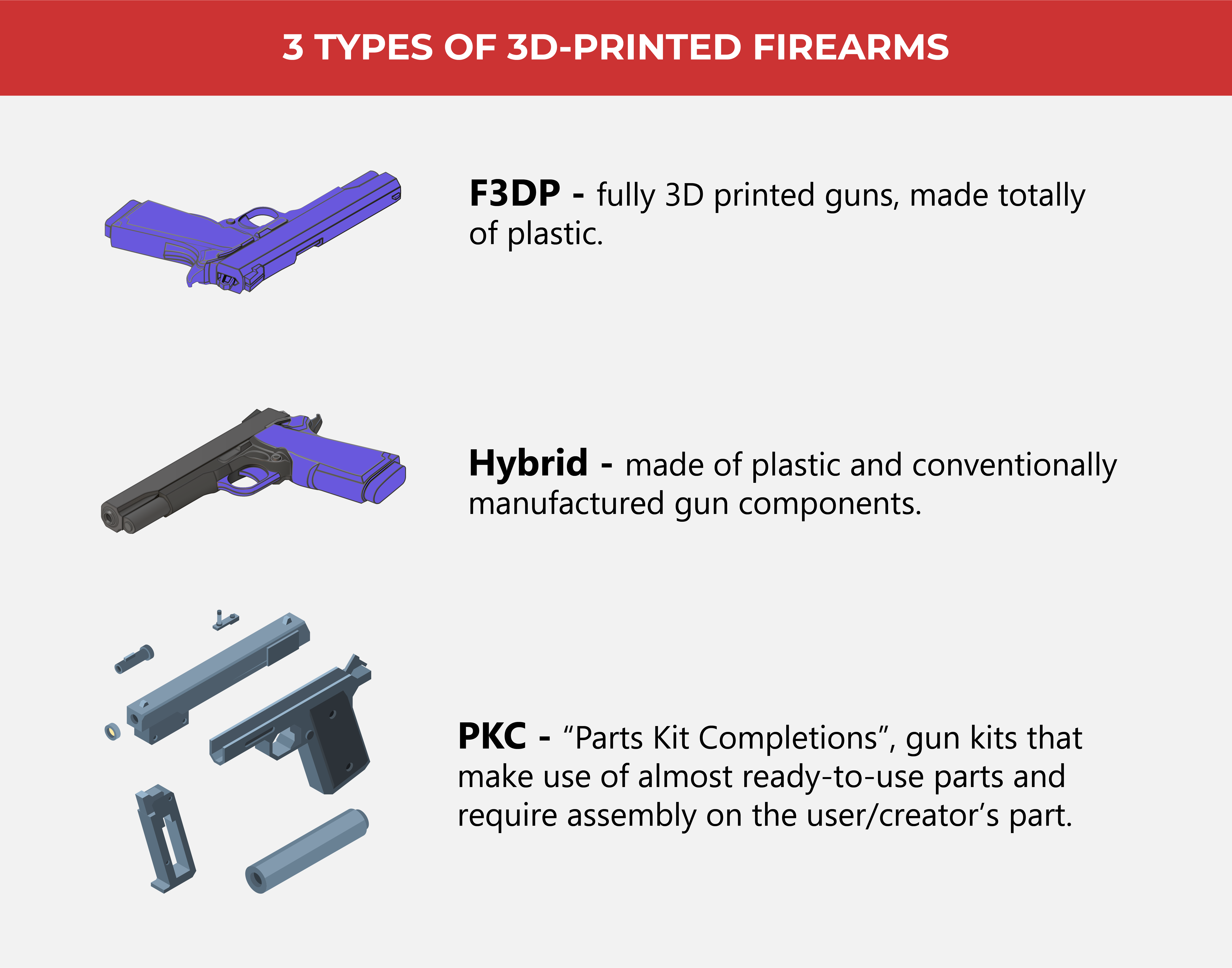

It wasn’t until 2013 that the first fully functioning 3D- printed gun was produced. Called the Liberator, this firearm was F3DP, meaning it was fully 3D printed and made totally of plastic. Its creation is credited to Cody Wilson, founder of an online open-source hardware organization known as Defense Distributed. Their official website hosts CAD files for designing one’s own firearm, or some may call them, “wiki weapons”. Despite the wacky-sounding name, these weapons are the real deal.

The United States Department of State deemed the publication of such information tantamount to the illicit export of firearms and took down the designs only two days after Defense Distributed published these online. Wilson filed suit, claiming a violation of his Second Amendment rights, and won in 2018.

It wasn’t long after this that other organizations followed suit with their own designs and platforms for distributing information. An example of such a group is Solid Concepts, an additive manufacturing company that produced what was thought to be the first industrial-grade 3D printed firearm, the 1911 DMLS, which for all its intents and purposes was a replica of the Colt Government Model 1911.

Today, it is now possible to print firearms that behave much like their conventional counterparts, and they would just be as deadly. Semiautomatic rifles such as the FGC-9 (F*ck Gun Control-9) and the Scz0rpion are notably notorious models.

By 2021, these 3D-printed weapons would find themselves in the hands of not only gun enthusiasts and Second Amendment advocates, but guerilla fighters from Myanmar and neo-Nazis in Germany.

How the guns are made

Some think that printing a gun would be easier than acquiring a gun, but experts would argue that this isn’t necessarily true. While printing a gun is possible using a standard fused deposition modeling (FDM) desktop printer, it’s not that simple, and in countries outside of the United States, is considered illegal.

In the United Kingdom, laws surrounding firearm ownership and acquisition are stricter than in the United States. Authorities are now looking to crack down harder as the trend of 3D-printed guns appearing on the streets has risen considerably.

Apart from running afoul of the law, the printers used to make the 3D-printed guns do not come cheap. For the strictly curious, printers start at 150 British pounds.

3D-printed guns are made by printing layer after layer of thin, fibrous plastic lines atop a build plate until a three-dimensional model is made. Thermo-plastic polymers such as PLA and its tougher variant PLA+ are used. Both variants are relatively cheap, affordable but brittle and prone to breakage. Materials such as nylon and polycarbonate are also used, but these are more difficult to print.

Seizure, regulation, and the right to bear arms

There have been numerous news reports of 3D printed gun seizure around the globe. From Melbourne, Australia to Calgary, Canada, large-scale 3D fireams seizures are being reported. Because 3D guns are virtually unlicensed, it is near impossible to trace them. This is why 3D printed guns are also referred to as “ghost guns”, and this, along with the accessibility of information on how to make them is what makes these weapons very dangerous.

Second amendment advocates are staunch to invoke the right to bear arms whenever the discussion of stricter gun regulation and control comes up. The freedom to protect one’s property and freedom from any outside threat is always brought up, and the right to defend oneself will always be the ultimate reason for gun ownership. The question remains: who are they defending themselves from? Who do they consider to be threats, and why?

The Washington Post says that the scope of gun-related violence in the United States goes far beyond mass shootings. Yet many are still denying the direct correlation between how easy it is to acquire a gun and the number of gun-related deaths in the country. Many would argue that the recent school shootings in Uvalde, Texas has nothing at all to with 3D printed guns, and they would not be wrong. However, there is a fundamental problem with guns in general that need to be examined first before anything else.

Protecting one’s own life and property is one thing, but when that right is taken to mean oppressing another person’s life and property, then it becomes a more nuanced, and far more vital conversation about freedom than it appears to be.

As one of the Top 19 EMS companies in the world, IMI has over 40 years of experience in providing electronics manufacturing and technology solutions.

We are ready to support your business on a global scale.

Our proven technical expertise, worldwide reach, and vast experience in high-growth and emerging markets make us the ideal global manufacturing solutions partner.

Let's work together to build our future today.

Other Blog