We guarantee customized test solutions of high quality and reliability in your products.

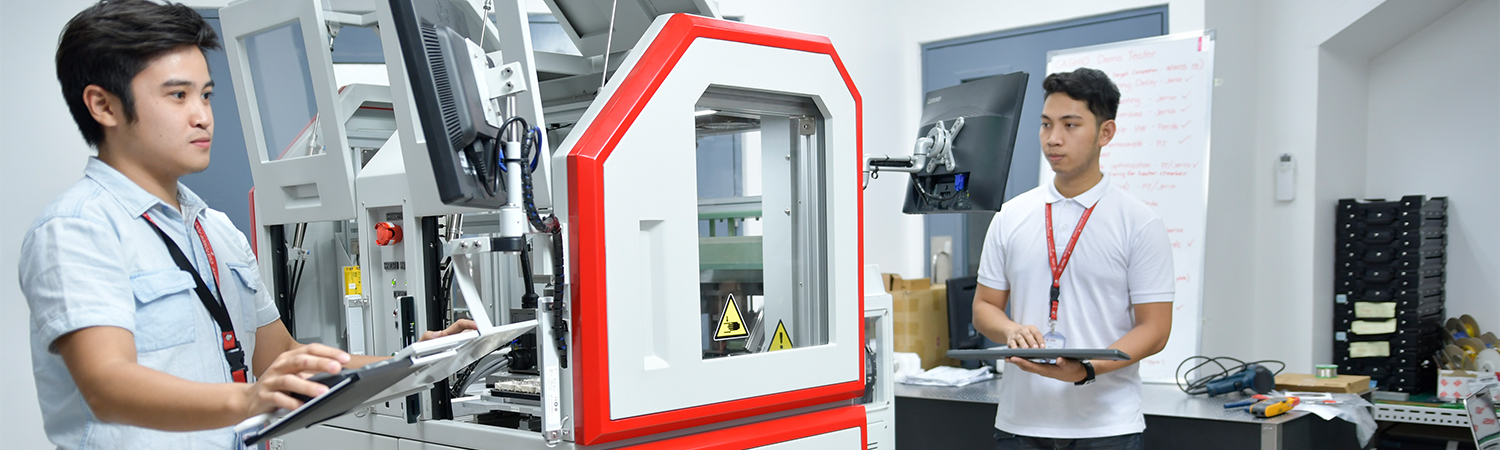

Robotic automation processes in many of our production facilities are implemented in various test platforms while sharing common software and hardware architectures.

Collaboration among our various TSD teams from different regions ensures continuous innovations in complex tester projects.

- Design for Testability

- Parallel test solutions

- Test coverage analysis & improvement

- Rapid turnkey hardware design and fabrication

- Flexible test platforms for product ECNs

- SW revisions

- Hardware field upgrades

- Test process and hardware documentation

- Training and 24x7 manufacturing

We have five TSD Centers of Competence with more than 70 engineers serving our global factory network.

We continue to innovate for sustainability, constantly rolling out customized test solutions for the EMS and automotive industry.

Our unique five-stage Tester Development Process involves a rigorous set of *gate check points* that help ensure compliance to quality standards and customer requirements.

AUTOMOTIVE TESTING

- 100% test coverage as well as functionality in harsh environmental conditions (i.e. low and high temperatures, pressure, humidity, vibration, etc.)

- Full Test Coverage

- Measurement Accuracy and Cage Repeatability

- Product Data Traceability

EFFICIENT PLATFORM-BASED SOLUTIONS

Parallel testing for upfront of products running at very high volumes and complex tests to enable quick support for sudden business growth requirements.

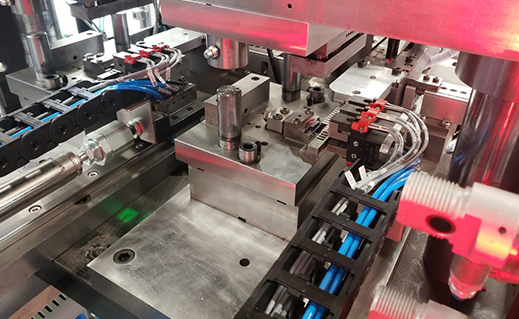

EMBEDDED AUTOMATION

- Our engineers carefully design the electro-mechanical systems during testing and back-end finish processes, while improving quality by eliminating errors incurred in manual operations and increasing overall throughput.

- We have a unique five-stage Tester Development Process with a rigorous set of *gate check points* that help ensure compliance to quality standards and customer requirements.