Why Solid-State Batteries Are the Next Best Thing for EVs

Electric vehicle (EV) companies consider solid-state batteries the next big thing in the OEM space. The race is on as key players in the electric automotive industry strive to build the first viable solid-state battery to make their products more efficient and consumer-friendly.

Since consumer electronics giant Sony first popularized the lithium-ion battery in the 1990s, it has entered mainstream applications. From small music players, this rechargeable battery is currently powering everything from smartphones and laptops to electric vehicles. Even lithium-iron-phosphate (LFP) batteries, which promise less pollution and boosted savings, are making waves. Still, these two battery types depend on a liquid electrolyte, which produces an electrical current by enabling the flow of ions between the electrodes.

With solid-state batteries, the liquid is substituted by a solid substance. These batteries may replace lithium with a wide range of materials, such as sulfides and ceramics.

However, the concept of solid-state batteries has been around for centuries. English scientist Michael Faraday discovered solid electrolytes, which generated labels like anion and electrolyte. Over the past years, solid-state batteries have become prevalent in handy electronic gadgets like radio frequency identification (RFID) tags and pacemakers for the heart.

Benefits of solid-state batteries

Why are OEM companies racing to develop this battery type? Here's a rundown of its upsides that will benefit consumers and the EV industry.

-

Increased energy density

Solid electrolytes provide more energy density than their liquid counterparts. How? Solid-state batteries can utilize lithium metal anodes, which offer more concentrated energy compared to the graphite anodes in typical batteries. This benefit comes with faster charging times and better driving range, giving users peace of mind on the road.

-

Boosted safety

Without the liquid electrolyte, this battery type becomes less prone to fires. There is always a risk of fluid leaks if the receptacle is damaged during a vehicular accident. Additionally, solid-state batteries can tolerate extreme temperatures, including high heat, which translates to safer charging.

-

Better for the environment

Some solid-state battery models don't use lithium, which is scarce and employs mining processes that harm the environment. These innovative batteries also have cathodes that are heavy on nickel, which reduces the reliance on cobalt. Like lithium, cobalt is in short supply and is typically mined in abusive conditions.

-

Smaller and lighter EVs

Because solid-state batteries tend to be smaller and lighter, EV companies can also reduce the size and weight of EVs without compromising range. More compact EVs generate less impact on infrastructure and the environment. They are less of a threat to pedestrians and cyclists. With more energy density and less weight, these batteries may also be compatible with producing electric aircraft.

Challenges solid-state batteries need to hurdle

Despite the numerous benefits of solid-state batteries, they also have their fair share of challenges they must overcome.

-

Delicate production process

Solid-state batteries are quite vulnerable to moisture, humidity and oxygen, which makes their assembly process complex and costly. Once contaminated with these elements, the battery's performance will be weakened.

-

Structural issues

It's also a challenge to ensure the optimal connection between the electrodes and electrolytes wedged between them. Repetitive charging and discharging can lead to fissures between these elements, which reduce the battery's longevity.

-

Long road to validation

For batteries to be validated and adopted by the industry, they must meet safety, longevity, performance, cost, and environmental impact standards. Some experts predict that it would take at least a decade for solid-state batteries to reach the current status of lithium-ion batteries.

-

Rebuilding manufacturing lines

Manufacturers should initially set up battery production facilities for automakers to assess factory-grade cells in real-life situations, which may take two years to finish. Prototyping and distributing the products to consumers will likely run for about six months.

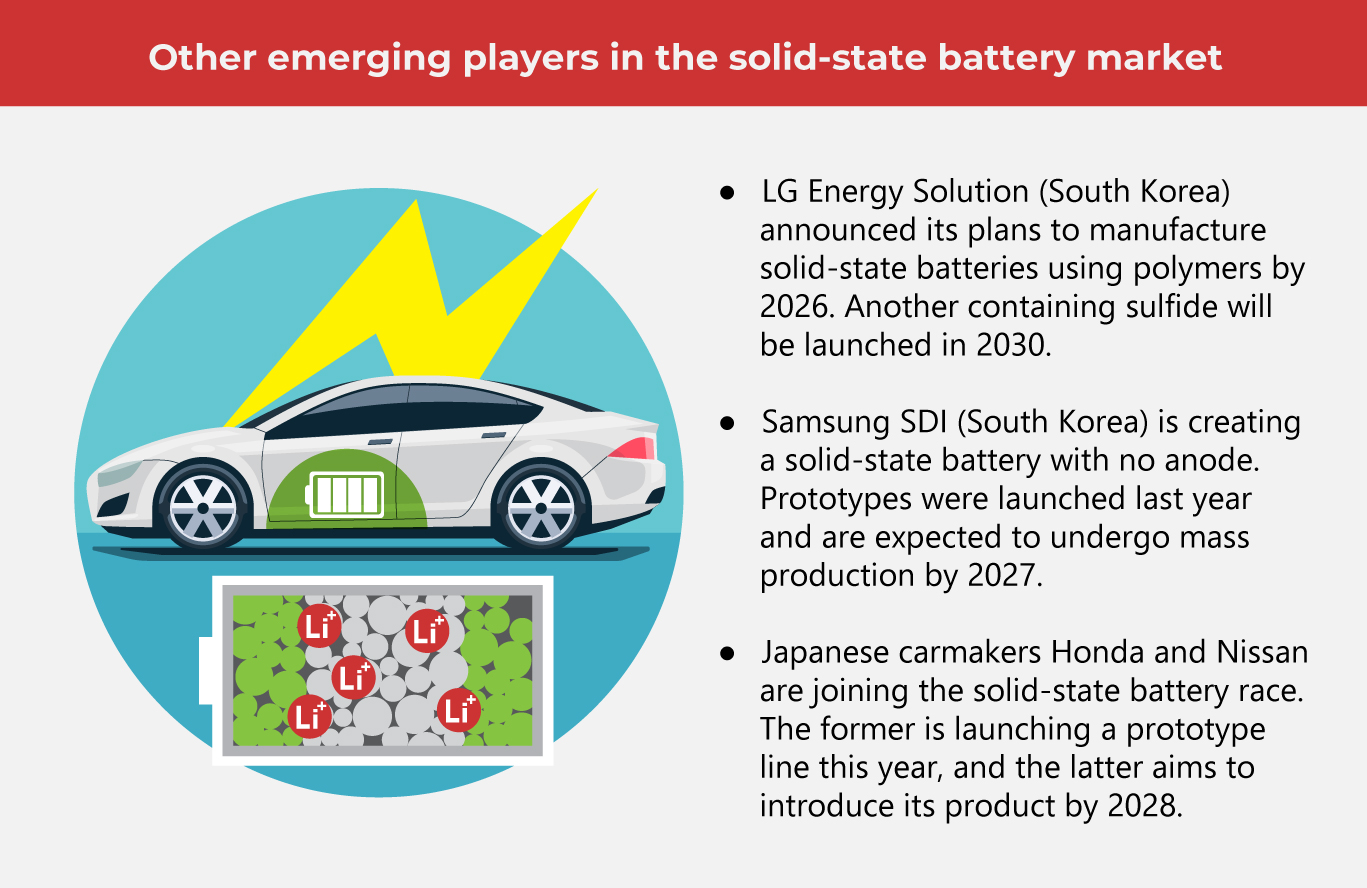

Global developments in solid-state batteries

Companies hope to strike gold with their ongoing research and development of solid-state batteries. Here are some notable breakthroughs produced by partnerships between automakers and tech companies.

-

Toyota & Idemitsu

In November 2023, Toyota entered a collaboration agreement with Idemitsu Kosan, the second-biggest oil refining company in Japan. Toyota mentioned in its press release that they've been working with Idemitsu on developing battery materials for over a decade. However, the recent agreement centers on commercializing and scaling up the production of solid-state batteries that contain sulfide electrolytes.

Toyota aims for their solid-state batteries to have a driving range of more than 1,200 kilometers and a charging time from 10 to 80% in a maximum of 10 minutes. While Idemitsu currently operates a scaled-down facility for electrolyte production, booth companies are building a bigger establishment that will combine materials production and battery manufacturing. With this move, Toyota hopes to churn out commercial batteries by 2027 or 2028, with mass production following.

-

Nio & WeLion

Chinese companies Nio and WeLion New Energy Technology have also teamed up to fast-track solid-state battery production by 2024. However, some experts emphasized that the battery is not strictly solid-state. Instead, it uses a gel electrolyte called lithium polymer, which has been around for 15 years. Gels are considered semi-solid and susceptible to punctures upon impact.

-

NASA

The US-based National Aeronautics and Space Administration (NASA) has extensively researched solid-state batteries. The projected output, made from sulfur and selenium, is primarily for aircraft use. However, should the experiment turn out well,

imagine the possibilities for EVs, which may boost their current driving range twice (or more).

-

BOLL.PA & BMW

This French company has penetrated the bus market, supplying them with solid-state batteries with a four-hour charging time. It is currently developing a solid-state car battery, using a polymer electrolyte and super-slim lithium metal anode. The product is targeted to have a charging time of 20 minutes at the most, boosting the range to almost a thousand kilometers. BOLL.PA has signed a partnership agreement with BMW. While solid-state is a significant breakthrough, it will take time before it's commercially viable for EVs. Still, developing it is worth the time and effort. While it can potentially transform the transport industry and lower its emissions, the solid-state technology can also be used for residential energy storage, further lessening our carbon footprint.

While solid-state is a significant breakthrough, it will take time before it's commercially viable for EVs. Still, developing it is worth the time and effort. While it can potentially transform the transport industry and lower its emissions, the solid-state technology can also be used for residential energy storage, further lessening our carbon footprint. As one of the Top 20 EMS companies in the world, IMI has over 40 years of experience in providing electronics manufacturing and technology solutions.

As one of the Top 20 EMS companies in the world, IMI has over 40 years of experience in providing electronics manufacturing and technology solutions.

We are ready to support your business on a global scale.

Our proven technical expertise, worldwide reach, and vast experience in high-growth and emerging markets make us the ideal global manufacturing solutions partner.

Let's work together to build our future today.

Other Blog