What’s So Funny about Enteric Methane Emissions?

The Food and Agriculture Organization of the United Nations says that methane accounts for 20% of global greenhouse gas (GHG) emissions and is more than twenty-five times as potent as carbon dioxide for trapping heat in the atmosphere.

According to the World Wildlife Federation (WWF), 70% of enteric methane comes from ruminants such as sheep, goats, and especially cattle. Their gastrointestinal releases (a.k.a. burps) are primarily responsible for this. Enteric methane from cattle and other grazing animals is the largest source of greenhouse gas emissions in the daily supply chain.

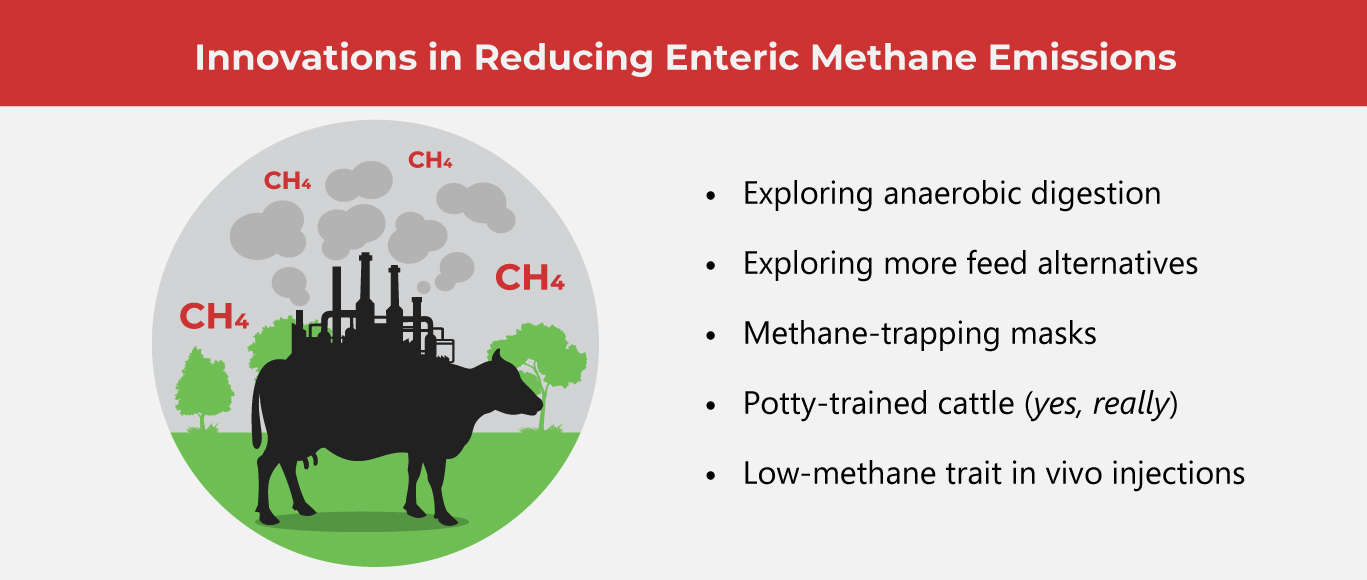

(Also Read: How Autonomous Agriculture Is Transforming Our Farms) The WWF enumerated a few innovations from scientists and researchers that are being used today to address this concern. Large-scale cattle farmers and agricultural companies from all over the world have been encouraged to look to these innovations as solutions to reduce GHG emissions.

The WWF enumerated a few innovations from scientists and researchers that are being used today to address this concern. Large-scale cattle farmers and agricultural companies from all over the world have been encouraged to look to these innovations as solutions to reduce GHG emissions.

Dairy farmers, along with processing cooperatives and companies in the United States have started a Net Zero Initiative (NZI) to show that their sector can do its part to significantly reduce GHG emissions.

A paper from the WWF cites four key areas of focus for the dairy farming sector’s NZI. These include feed production and practice changes; cow care and efficiency; on-farm energy efficiency and renewable energy usage; and manure handling and nutrient management.

Most of the innovations below focus on the first and second key areas: feed practice changes and cow care.

Anaerobic Digesters

Innovations in anaerobic digestion fall under the first key area. Here, manure is used to create renewable energy or natural gas. An anaerobic digester is a system for biologically converting biodegradable organic materials such as food waste and manure into methane, carbon dioxide, and water. Digesters help reduce odors, manage nutrients, and help farmers earn additional revenue from the bi-products produced.

“There’s an added benefit of avoiding methane emissions if food waste is diverted from landfills and added to the digesters,” WWF says.

Exploring Feed Alternatives

A large part of feed production and practice changes concentrates on searching for better alternatives for cattle feed. In most feed additives today, the primary ingredient is 3-nitrooxypropanal, or 3-NOP, which according to agricultural experts has been effective in inhibiting methane in cattle’s digestive systems.

The addition of seaweed and algae to this feed was discovered by Australian researchers. The digested seaweed prevents microorganisms inside the cow’s first stomach from producing methane.

In 2023, farmers in Sweden adopted the seaweed-powered methane-reducing 3-NOP upon the recommendation of agriculture experts. The Guardian reports that the chemical can cut emissions by an average of about 40% in dairy cows and by 45% in meat cattle.

Meanwhile, a Swiss agri-tech company called Mootral makes a natural cattle feed supplement they claim “significantly reduces methane emissions from ruminants. The company says that its formula consists of a proprietary combination of active compounds from garlic and bioflavonoids from citrus.

Will Mootral give companies that produce 3-NOP a run for their money? The challenge for exploring feed alternatives and supplements is that these discoveries need research support. While observations appear to lean towards the positive, the long-term effects on the animals, the environment, and the people consuming meat and milk are inconclusive.

Ample support for research funding to measure and evaluate the safety, sustainability, and scalability of these feed ingredients, alternatives, and supplements is much needed. A push for policy-makers to advocate for agricultural research especially those aligned with NZI is also needed.

Methane-trapping Masks

While many scientists in agriculture focus on exploring feed ingredients and supplements, other researchers are instead looking into tools that care for the animals and help reduce enteric methane.

A company based in the UK called Zelp has created masks that livestock can wear to reduce enteric methane emissions. Zelp was founded by brothers Francisco and Patricio Norris, whose family are from Argentina and own a livestock farming business. The brothers think that methods for mitigating enteric methane emissions are under-researched, so they came up with a solution that does not interfere with the diet of the livestock because 95% of enteric methane emissions come from the cow’s nostrils and mouth.

Zelp’s masks are adjustable and fit over the cow’s head in a harness, with the mask fitting over its nose. A sensor at the tip of the mask detects the percentage of methane the cow expels when it exhales. Once the methane level gets too high, the mask converts the methane into carbon dioxide and water.

Potty-trained Cattle

This may sound a little out of left field, but have you heard of potty-trained cattle? In 2021, The Economist ran a feature on Dr. Jan Longbein and his team of researchers from the Freidrich-Loeffler Institute in Germany for their work in training cows to urinate in a specific area.

According to the article, cow urine contains urea, which gets converted into ammonia, contributing to GHG emissions. Their study was mostly successful, but it does need continuous research for enteric methane emissions, and overall scalability. However, as silly as it may sound, the study becomes the basis for future studies that may benefit thousands of farmers.

A Low-methane Trait in In Vivo Injections

In vivo injections for producing cattle that emit less methane exist. Reuters reports that the arrival of commercially available genetics to produce dairy cattle that emit less methane could help reduce one of the biggest sources of GHG emissions.

The company claims that the injection can “reduce methane emissions from Canada’s dairy herd by 1.5% annually, and up to 20% to 20% by 2050.

As one of the Top 20 EMS companies in the world, IMI has over 40 years of experience in providing electronics manufacturing and technology solutions.

We are ready to support your business on a global scale.

Our proven technical expertise, worldwide reach, and vast experience in high-growth and emerging markets make us the ideal global manufacturing solutions partner.

Let's work together to build our future today.

Other Blog