What to Know about Recycling EV Batteries

Experience and foresight guide OEMs and researchers to seek solutions for recycling EV batteries before they become a problem.

The Electric Vehicle World Sales Database projected that global sales comprising battery-electric vehicles (BEVs) and plug-in vehicles (PHEVs) would reach 14.1 million units in 2023. Meanwhile, BloombergNEF’s Electric Vehicle Outlook 2023 reports there could be as many as 700 million EVs on the road worldwide by 2040.

(Also Read: How EV Batteries are Tested)

While it may be true that we’re not all driving EVs just yet, these numbers are painting an inevitable picture with an outcome that needs to be addressed as early as now.

An EV battery’s life can last anywhere from 8-12 years. Some OEMs claim that EV batteries can last up to 20 years. Mileage-wise, most would peg it at an average of 241,000-321,000km or 150,000-200,000 miles. Car and Driver says that an EV battery is at the end of its life when it has no more than 70 to 75% of its original capacity.

So, what happens at the end of an EV battery’s lifespan?

Many of us are mindful of how we dispose of the batteries of our smaller electric devices, but some simply toss those AA batteries in the trash. That won’t be the case for EV batteries because of its size and what it’s composed of.

Can EV batteries be recycled? The short answer is yes.

Reusing EV Batteries

Though the battery may no longer have enough energy to power any vehicle, it can still contain some energy that can still be harnessed for use elsewhere. Reuse and re-purpose of EV batteries is possible, even though it hasn’t yet been done to scale.

Elsa Olivetti, a professor of materials science and engineering said that blocks of old batteries could be used to ease strain on the power grid by providing back-up when it’s needed the most.

Similarly, Nissan used old EV batteries from their Leaf EV to power a stadium in Amsterdam in 2018.

The business of Recycling EV Batteries

Let’s not forget that an EV battery is made up of precious minerals such as aluminum, copper, manganese, and other metals that are still usable.

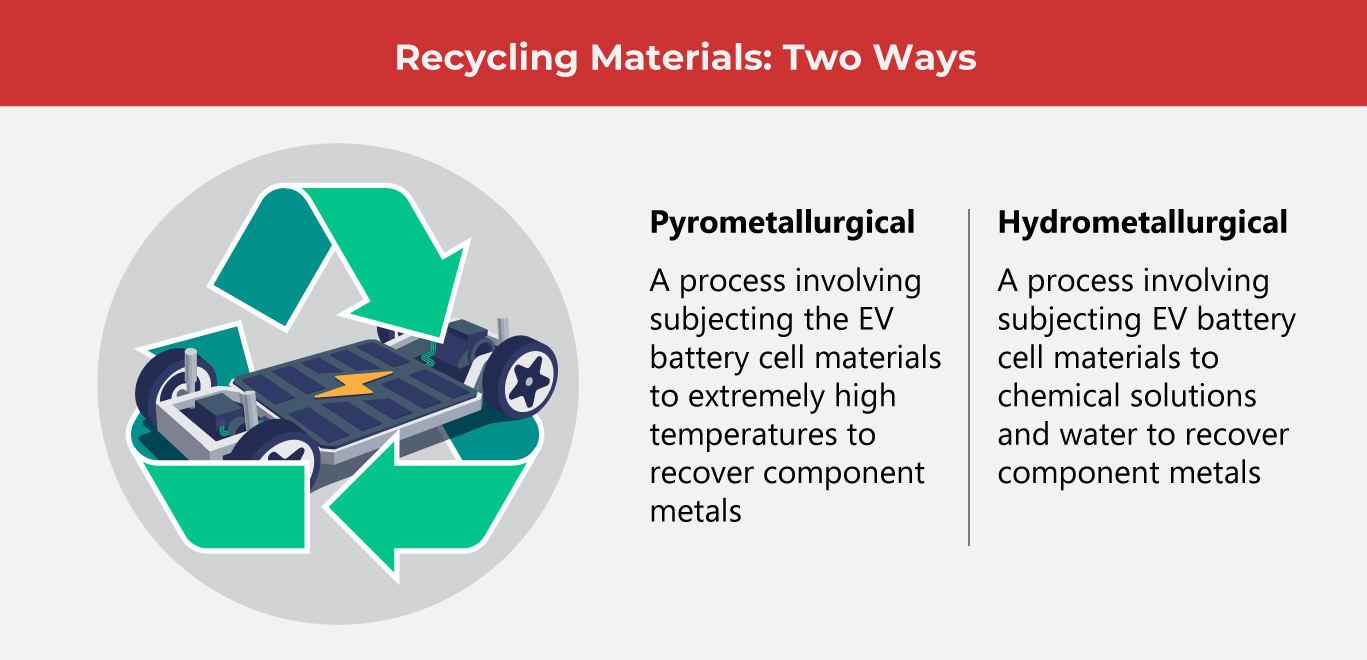

Auto recyclers send the EV batteries to special facilities where the battery packs are broken down into separate components: wires, plastic, cells, circuitry, etc. The cells are crushed, then the metals are sorted out.

Recycling EV batteries is a complex process involving many steps and special equipment. This is why scientists and OEMs are finding solutions that can eventually be scaled up.

Scientists from the Department of Materials Science and Engineering (DMSE) and the MIT Climate and Sustainability Consortium say that the EV battery recycling business will be driven by which materials are most profitable to salvage.

Professor Elsa Olivetti says that in the case of lithium-ion batteries, these materials are metals such as nickel and cobalt.

Other metals found in the EV battery cells such as lithium, manganese, and aluminum are valuable also. When these metals are taken from the EV batteries, they undergo a purifying process so that these metals can be used once again.

Scientists from Sweden have found a method of EV battery recycling that recovers 100% aluminum and 98% lithium. According to Euronews, their method does not require the use of expensive or harmful chemicals.

Researchers from Chalmers University of Technology reportedly use a method that “involves the order of the current [hydrometallurgical] process and recovering the lithium and aluminum first.”

Other scientists meanwhile are discovering that bio-based solutions could also be viable. Experts in biotechnology from the University of Edinburgh say that engineered bacteria could be used in recovering precious metals from EV battery cells.

Professor Louise Horsfall and her team have been studying bacteria to extract cobalt, manganese, lithium, and nickel.

According to The Manufacturer, the team used a fermenter consisting of bacteria added to EV battery leachate (liquid remaining after the initial process) to “stimulate a natural biologic reaction. During the process, the bacteria produce nano-sized particles of metallic compounds, resulting in a sediment that can be separated and filtered out from the residual liquid.”

“We need to consider what happens to technology when it is no longer fit to use,” Professor Horsfall said about the significance of the project and stressed that it is about “using cutting-edge sustainable biotechnology to find ways of tackling that challenge.”

Several OEMs are putting themselves up to the task as well. Some of these scientists, such as the researchers from Chalmers, are working with Volvo and Northvolt. Nissan has been exploring EV battery recycling since 2018.

Many OEMs are getting on board as they see not only a solution to a future problem but also because EV battery recycling is very profitable. McKinsey projects that by 2025, battery material could be worth up to $600 per ton.

As one of the Top 20 EMS companies in the world, IMI has over 40 years of experience in providing electronics manufacturing and technology solutions.

We are ready to support your business on a global scale.

Our proven technical expertise, worldwide reach, and vast experience in high-growth and emerging markets make us the ideal global manufacturing solutions partner.

Let's work together to build our future today.

Other Blog