What Does a Stress Testing Engineer Do?

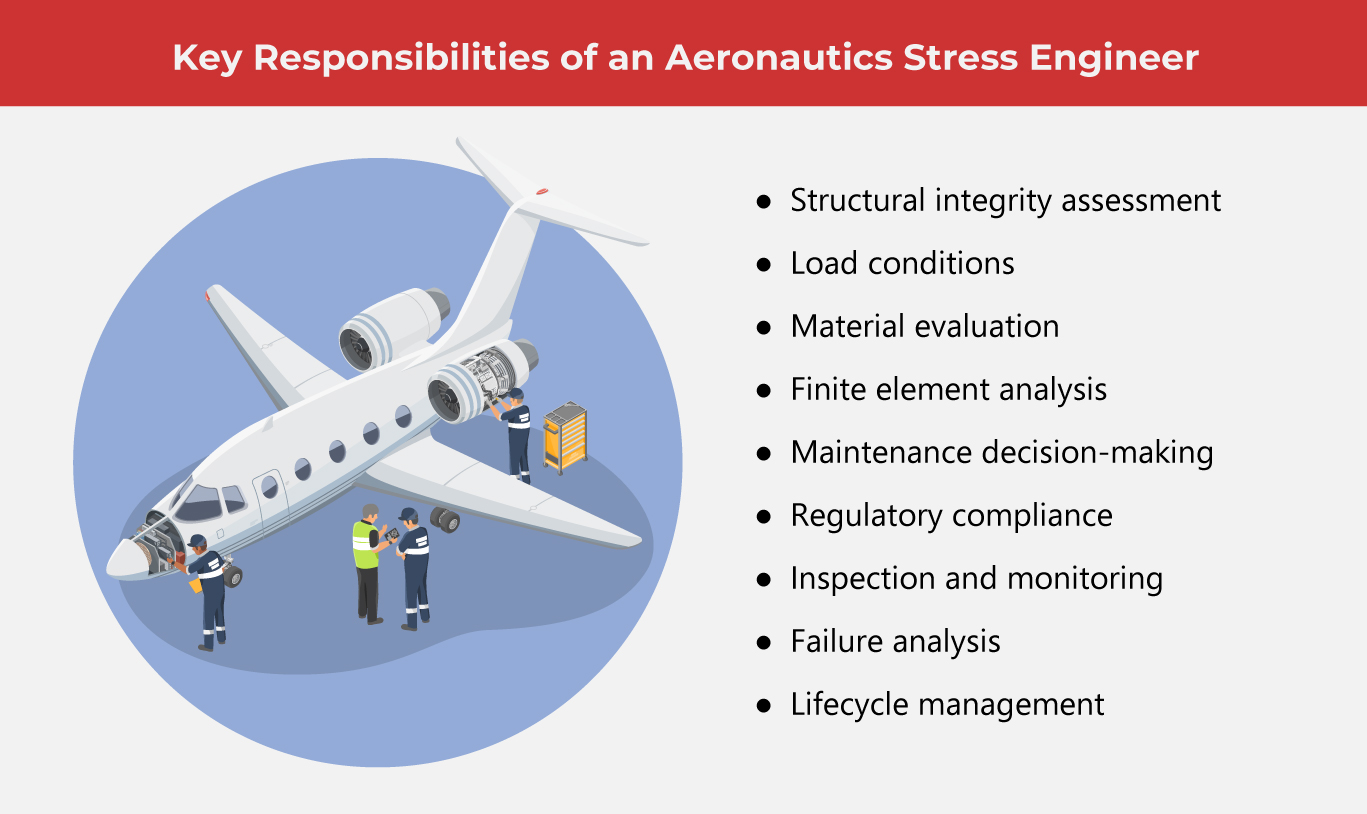

A stress aeronautics engineer ensures the structural integrity of aircraft (and spacecraft) and its components.

We know an aircraft has passed the engineer’s rigorous stress testing when an aircraft takes off and lands safely. These engineers perform several tests taking into consideration materials, geometries, loads, and operational conditions. All these components need to adhere to regulatory safety standards.

(Also Read: Are Flying Cars Ready to Take Off?) Aeronautics stress engineers assess the structural integrity of aircraft and its components. They evaluate materials and structures to ensure they can withstand various loads and stresses during flight. Structural analysis makes use of computational methods such as finite elements analysis (FEA). Software such as ANSYS or Abaqus and other computation tools are used to ensure components satisfy their mechanical durability requirements. These help evaluate the condition of an aircraft and its components such as its wings, frames, and engines. Stress engineers should be able to identify signs of wear and tear, fatigue, and damage that may compromise safety.

Aeronautics stress engineers assess the structural integrity of aircraft and its components. They evaluate materials and structures to ensure they can withstand various loads and stresses during flight. Structural analysis makes use of computational methods such as finite elements analysis (FEA). Software such as ANSYS or Abaqus and other computation tools are used to ensure components satisfy their mechanical durability requirements. These help evaluate the condition of an aircraft and its components such as its wings, frames, and engines. Stress engineers should be able to identify signs of wear and tear, fatigue, and damage that may compromise safety.

The results stemming from the initial analyses will further be tested by another layer of testing that includes software and algorithms for the following:

- Burst/Strength

- Fatigue

- Bolted joints

- Welded joints

- Frequency avoidance

Stress engineers analyze load conditions during flight, including static loads (such as weight and aerodynamic forces) and dynamic loads (such as turbulence and maneuvers).

They also oversee and interpret the results of the various tests to vet and validate that the components meet safety and performance standards.

Stress engineers do not work in silos. Rather, their work is highly collaborative, working with their counterparts across several disciplines. These include systems, manufacturing, quality assurance, and design.

Collaborating with design engineers ensures that safe and efficient aircraft components are produced. Stress engineers provide invaluable input on materials selection, geometry, and safety.

Preparing technical reports, collecting documentation, and generating presentations for stakeholders and regulatory entities are also important parts of a stress engineer’s job. They ensure that aircraft designs comply with established industry standards governed by authorities such as the Federal Aviation Association (FAA) and the European Union Aviation Safety Agency (EASA).

Failure analysis is also included in an aeronautics stress engineer’s purview. They investigate structural failure and anomalies discovered in aircraft components and identify root causes to make recommendations for improvement.

Lifecycle management, which includes the aircraft’s maintenance, is also considered. From design to maintenance to retirement of components, a stress engineer’s eyes are attuned to finetuning and taking care of the aircraft’s components and ensuring the best conditions for its next flight.

Four skill sets are integral to the job. First, a stress engineer must possess exceptional analytical skills. Problem-solving skills coupled with high-level skills in mathematics are the baseline requirement for them to perform complex analyses. Results from the tests performed must be precise, and meticulous attention is vital.

Software proficiency is a must. The tools used today for aeronautics stress engineering are very advanced. Software such as SimScale and COMSOL, and engineering design tools such as CATIA are just some of the staples that engineers have in their toolbox.

Apart from these, aeronautics stress engineers must be strong communicators to convey complex interpretations to other teams, stakeholders, and governing bodies. They should be able to simplify and translate the numbers into tangible, actionable solutions.  As one of the Top 20 EMS companies in the world, IMI has over 40 years of experience in providing electronics manufacturing and technology solutions.

As one of the Top 20 EMS companies in the world, IMI has over 40 years of experience in providing electronics manufacturing and technology solutions.

We are ready to support your business on a global scale.

Our proven technical expertise, worldwide reach, and vast experience in high-growth and emerging markets make us the ideal global manufacturing solutions partner.

Let's work together to build our future today

Other Blog