What Is Contract Manufacturing

Contract manufacturing is an outsourcing practice where a company hires a manufacturer to make their products.

From electronics to automotive, cosmetics to pharmaceuticals, contract manufacturing is indispensable in getting customers what they need.

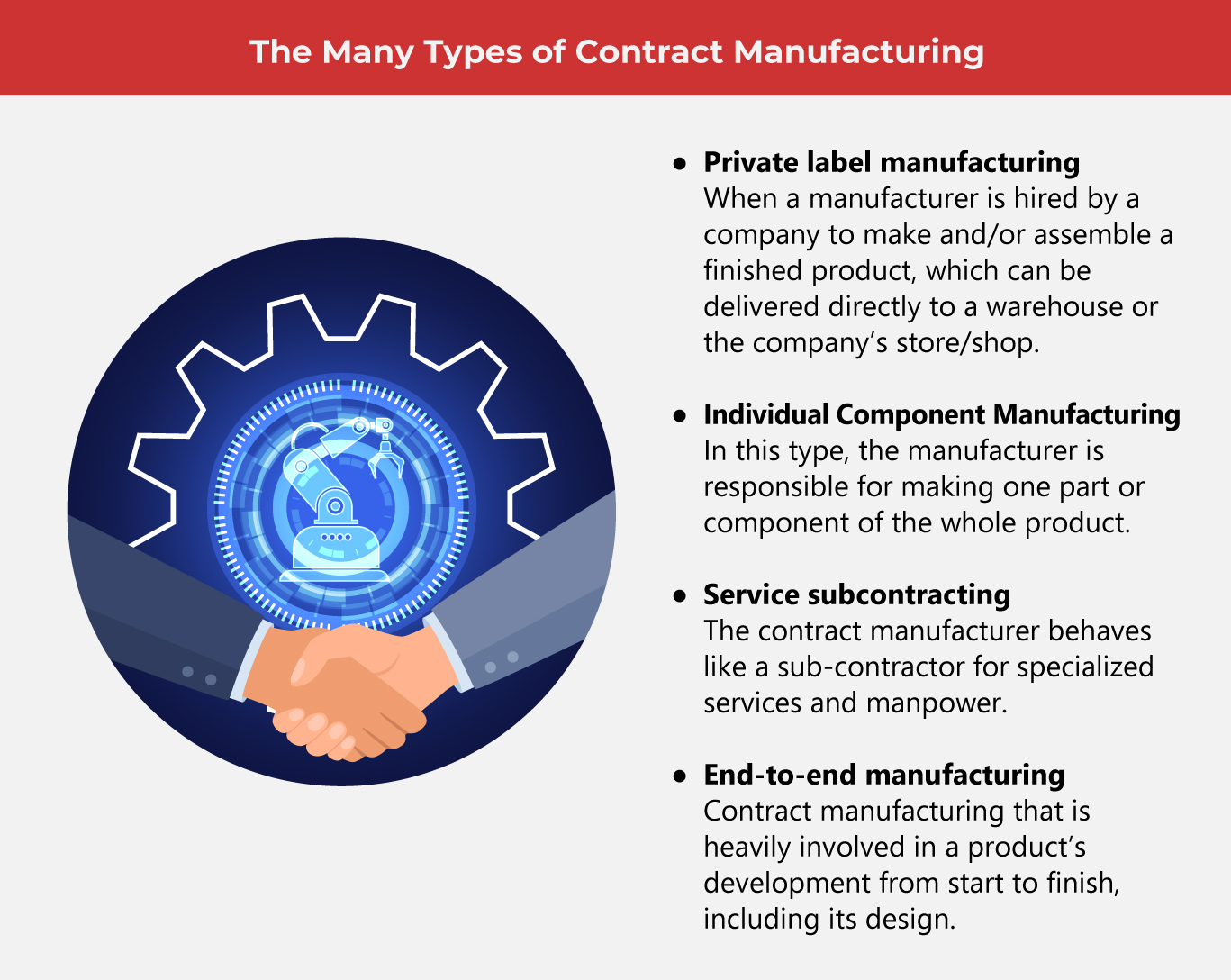

A practice that allows companies to hire third-party manufacturers to help produce a product and its components, contract manufacturing takes on many forms and types, depending on what the company requires. Let’s take a closer look at what those are, and delve into some of the benefits and challenges of contract manufacturing.

(Also Read: How Circular Manufacturing Can Save the World)

According to the Project Manager, when a business does not have the resources to invest in the machinery needed to make a product, it can collaborate with or hire another company with the capabilities to produce that product. This is outsourcing on a manufacturer’s level, and third-party manufacturers provide many benefits for the companies they have agreements with.

Why Choose Contract Manufacturing for Your Business?

Why Choose Contract Manufacturing for Your Business?

Contract manufacturing offers businesses many benefits. First, it’s a practice that keeps costs down. Companies can reduce overall costs by collaborating with or outsourcing manufacturing. Businesses do not need to purchase equipment or build facilities to come up with their product. Further, companies need not hire or train additional manpower to create these products.

Companies can save more with contract manufacturing. By reducing labor costs and eliminating investments in equipment, companies drive up savings.

When it comes to scale, contract manufacturing allows companies to bring scalability to their businesses. Smaller companies that need to fulfill large orders of one or several products benefit a lot from outsourcing. One can easily increase or reduce the manufacturing capabilities depending on the market size when outsourcing.

A faster turnaround time is also another great thing about contract manufacturing. Since the manufacturer already has the machinery, equipment, and services in place, timelines for delivery are a lot smoother and more efficient.

With the proper guidance and direction from the client company on the precise design, specs, and quantity of the product, the manufacturer can concentrate on getting the job done much quicker.

Improved quality is also a consideration of many companies when they outsource. Manufacturers observe standards certified by a governing body called the International Organization for Standardization (ISO). When something is ISO-certified, this guarantees that the product manufactured has undergone rigorous testing to ensure its quality.

Challenges of Contract Manufacturing

While contract manufacturing is very much practiced by many sectors of industry, it doesn’t come without its challenges, especially when it comes to the supply chain.

For smaller and newer companies, it might be more of a challenge to find the right manufacturer for their business. Concerns regarding quality control and security are a couple of common challenges business face with contract manufacturing.

While it’s true that this practice can lower costs significantly, there may be certain trade-offs involved, and if the business hasn’t done its due diligence before getting into an agreement with the manufacturer, quality may suffer.

Many companies have their trade secrets—that special design element or ingredient that makes their product stand out in the market. These are heavily guarded so that no other business can make copies of a particular product. OEMs from automobile makers to sneaker brands protect their designs to avoid scenarios where knock-offs can be made and sold without the OEM ever making a cent out of their designs.

Compliance and quality control are also part of the challenge. Businesses need to do their research on the manufacturer they are taking on for their projects. Selecting reputable manufacturers with clean track records of performance and are ethical is tantamount to ensuring the quality of their output.  As one of the Top 20 EMS companies in the world, IMI has over 40 years of experience in providing electronics manufacturing and technology solutions.

As one of the Top 20 EMS companies in the world, IMI has over 40 years of experience in providing electronics manufacturing and technology solutions.

We are ready to support your business on a global scale.

Our proven technical expertise, worldwide reach, and vast experience in high-growth and emerging markets make us the ideal global manufacturing solutions partner.

Let's work together to build our future today.

Other Blog