Top Automation Trends in Construction in 2024

According to industrialists, automation will drive the construction industry in 2024. Learn the methods, tools, and trends shaping one of humanity's most important industries, changing the blueprint for construction businesses' operations.

The construction industry is an institution in the field of modernization. From paving roads to building infrastructure and homes, this sector has been and continues to be vital in humanity's daily activities and the global economy.

However, the construction industry leaves a lot of room for improvement. It releases significant amounts of carbon dioxide into the atmosphere, contributing to global warming. Processes can be made more efficient and structured. Meanwhile, construction workers are typically not paid well even though they're often exposed to unsafe situations.

Despite these issues, the industry has barely shifted. While automation and digitalization have transformed fields like manufacturing, agriculture, and transportation, construction has yet to embrace them fully. In fact, an ABB-led survey revealed that out of the 1,900 construction companies interviewed, only 55% utilize robotics. This is a small figure compared with 79% in global manufacturing and 84% in the automotive market.

Still, robotics shows promising capabilities in the field of building—and businesses are starting to realize this. The same survey also shows that over 80% of construction companies intend to implement or expand their use of automation and robotics in the coming decade. As a result, experts predict construction automation will increase by 85% by 2030, a strategy to meet the growing demand for new and more efficient housing.

The recent partnership of ABB Robotics and Porsche Consulting is proof of the boosted interest in construction automation. They combine their expertise to create inventive approaches to manufacturing modular housing. The team hopes to transform the industry by leveraging automation and improving productivity, efficiency, and sustainability.

Why should we automate construction?

A McKinsey report states that the industry has the potential to automate 47% of its tasks. Aside from using robotics in actual building, automation can assist in identifying issues and keeping track of progress and documentation. With this kind of backup, the construction industry can reap these benefits:

- Boosted safety

Robots can replace humans in risky, repetitive and potentially toxic construction tasks. These include accurately placing objects, heavy lifting, erecting high-rise structures, and processing materials. Moreover, ABB states that construction workers contribute to approximately 30% of workplace accidents and face four times as much risk for fatal injuries compared to other industries.

- Addressing skill and labor gaps

Aside from manufacturing, construction is also undergoing labor shortage, which compounds the housing crisis in several countries. While the US has a shelter deficit of almost four million homes, Germany may grapple with dwelling supply scarcity in its 35 cities by 2030.

- Lowered housing costs and increased efficiency

Automation and robotics can take on extensive manual labor, speeding up the construction timeline and allowing companies to reduce their workforce. Better precision in automated construction methods also reduces material wastage. Businesses can automate documentation that helps in cost forecasting and monitoring. All these cost-cutting measures result in more affordable homes for more people.

Through precise material handling, businesses can maximize resources while minimizing waste. Automation can also integrate innovative designs and systems that conserve energy or use renewable power sources. With a streamlined process, the construction industry significantly manages its environmental impact.

- Greater flexibility

Systems fueled by robotics and automation can carry out sophisticated tasks, making customized architectural features possible. With a solid foundation of detailed plans and visualization, construction is made precise while leaving room for personalized designs and client-centered building sensibilities.

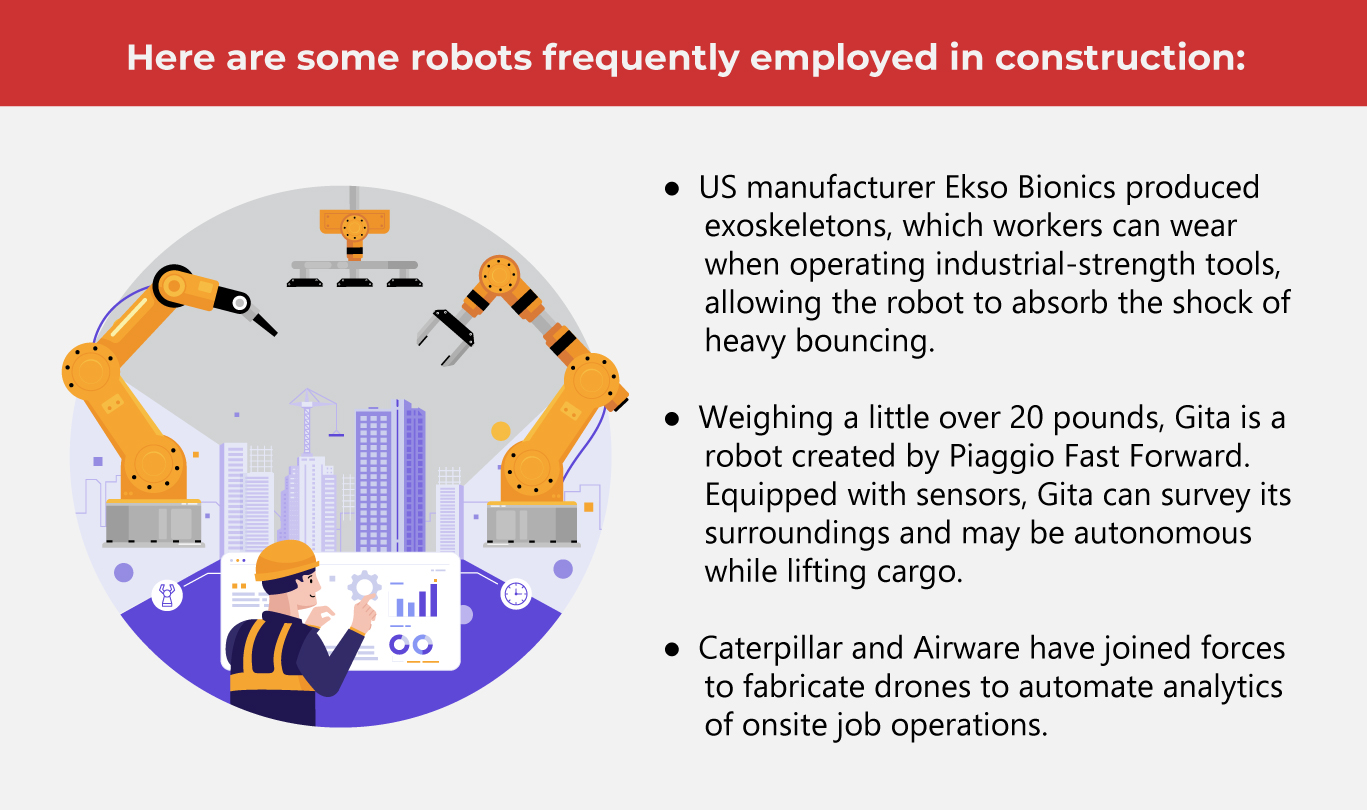

Top robotic and automation trends in construction

Automated construction techniques continue to evolve with these trends shaping its development.

- Offsite usage

Construction robots often work offsite, where conditions are consistent and routinary. Steps like precast, prefabrication, and panel construction are ideal for robots and follow a process similar to manufacturing. Components with predetermined shapes and structures can be produced in high volume, with room for variation. Once finished, these parts can be brought to the construction site for installation.

- Mobile robots

Because industrial robots are bulky and hefty, they can't be moved around, limiting their use. Researchers are addressing this by developing mobile robots like robotic arms, drones, and those that can literally cover more ground by aiding excavators. Minibuilders are also a type of mobile robot that can scale the structure they will construct. Meanwhile, fiberbots ascend onto the structure to complete its final framework.

- Customized robots

Scientists are also looking into robots designed for particular tasks. But the downside of customization is these mobile machines' limited abilities. For these robots to be viable, their production costs should be affordable. They should also be easily assembled and reprogrammed for easier utilization.

- Human-robot collaboration

While robots can work together to hasten production, they can also function alongside people. Such machines are called cobots, short for collaborative robots. Engineered to operate with humans, cobots follow precise safety guidelines to reduce workplace risks. Complementing their precision are humans, who are highly adaptable, able to adjust to sudden shifts and absorb complicated information immediately. Currently, strategies for safe and effective human-robot collaboration are being developed, particularly in the complex construction environment. So, are automation and robotics doable in a complex construction scenario? This move faces multiple challenges, including taking on the industry's large-scale operations. And while robots are thriving in off-site settings, the reality is that most building processes take place onsite.

So, are automation and robotics doable in a complex construction scenario? This move faces multiple challenges, including taking on the industry's large-scale operations. And while robots are thriving in off-site settings, the reality is that most building processes take place onsite.

Because construction settings are unpredictable, it's more challenging to use autonomous robots that are not programmed to react to every possible change. The most viable approach, then, is to employ people and robots, which need robust safety controls to ensure human protection.

For smart construction to fully develop and overcome these challenges, various fields like robotics, architecture, computer engineering, and others must work together. The potential of automation and robotics in construction cannot be ignored; it deserves to be explored for humanity's future. As one of the top 20 EMS companies in the world, IMI has over 40 years of experience providing electronics manufacturing and technology solutions.

As one of the top 20 EMS companies in the world, IMI has over 40 years of experience providing electronics manufacturing and technology solutions.

We are ready to support your business on a global scale.

Our proven technical expertise, worldwide reach, and vast experience in high-growth and emerging markets make us the ideal global manufacturing solutions partner.

Let's work together to build our future today.

Other Blog