Top 8 Advantages of PRM for Your Industry

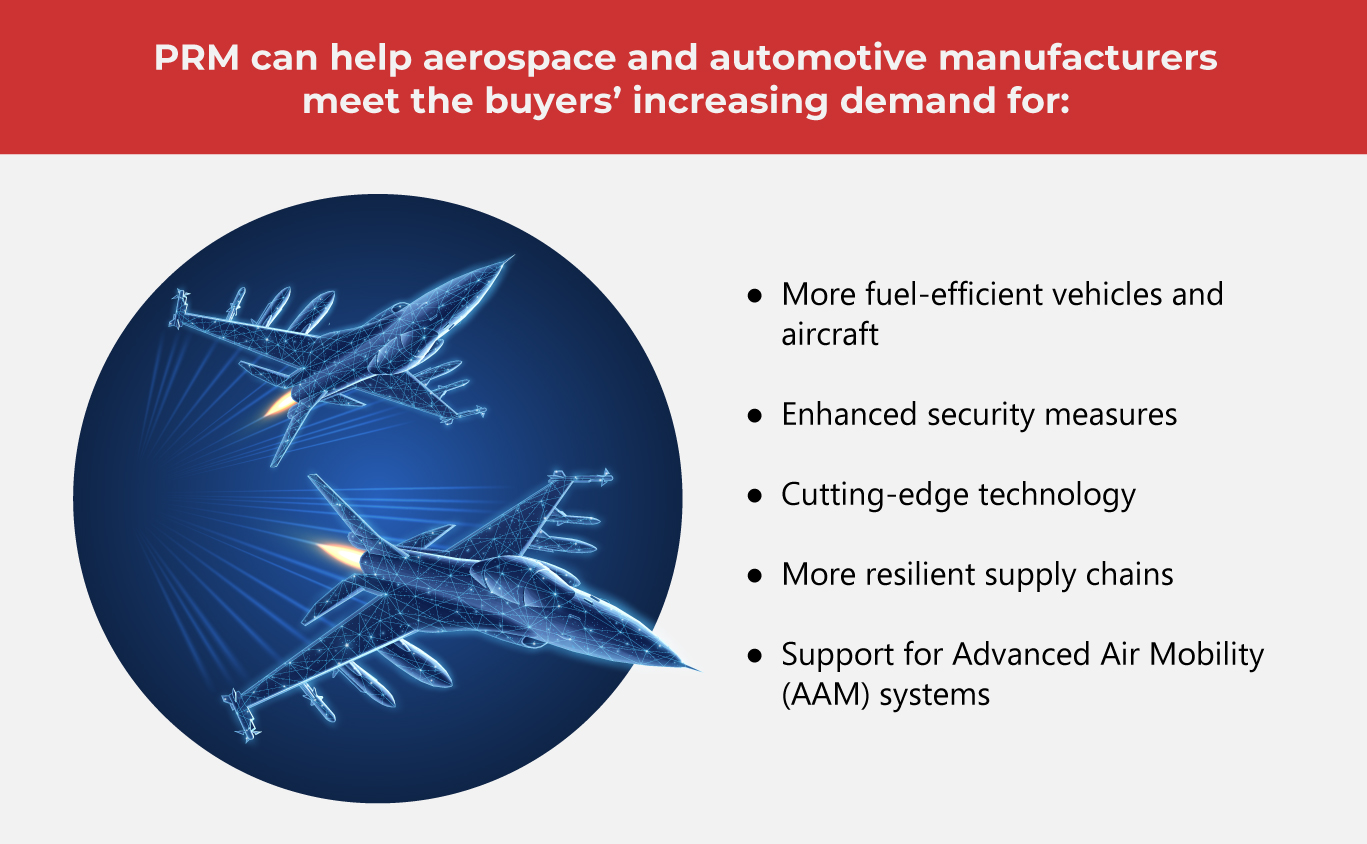

Manufacturers in various sectors gain from using communication and collaboration tools, with Product Roadmap Management standing out as one of the most thorough. In fields such as aerospace and automotive, where product quality can determine safety, effective production management is essential.

What is Product Roadmap Management (PRM)?

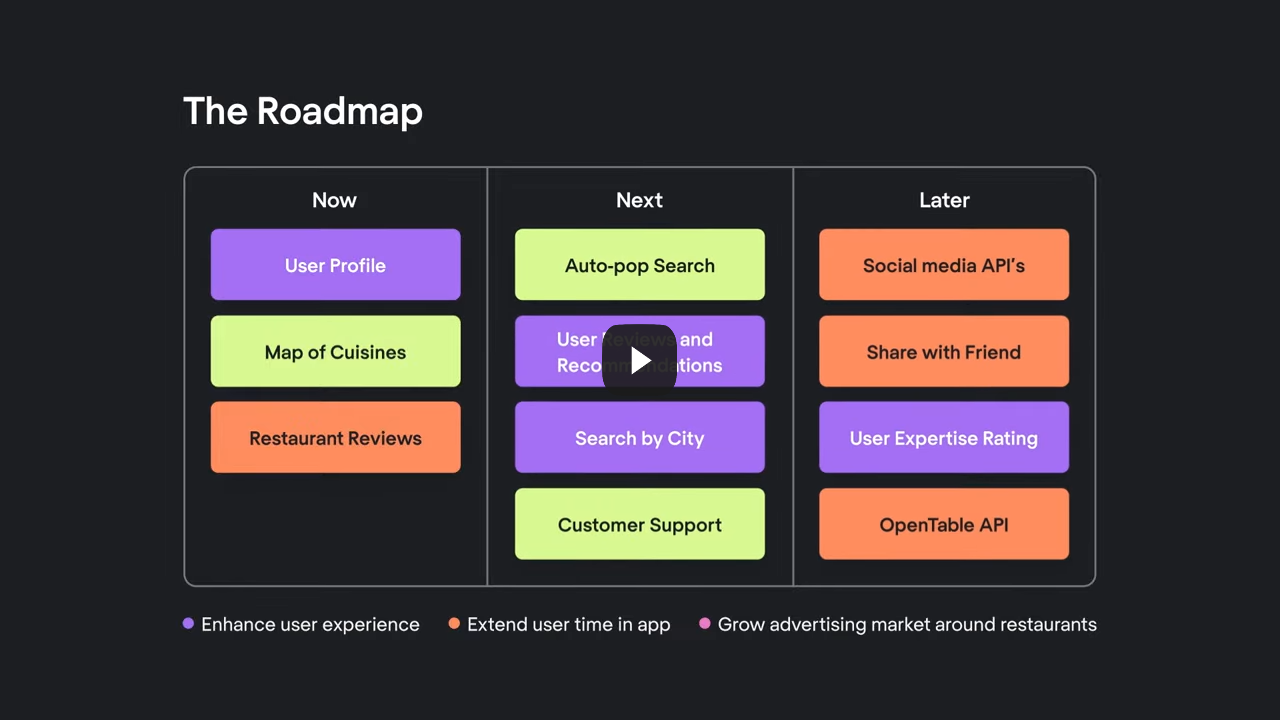

Product roadmap management monitors the full lifecycle of a product, from development and design to introduction and upkeep. In the aerospace industry and automotive market, product managers ensure products meet customer needs, safety standards, and remain competitive.

With the help of PRM software, teams can envision the product cycle in its entirety. This allows them to align timelines for product revision, testing, and launch, including finance and marketing. It ensures all stakeholders stay updated on milestones and technical details, improving operational efficiency and accuracy.

Understanding the aerospace industry

The aerospace industry plays a crucial role in civil aviation and space exploration, including the design and production of aircraft and spacecraft, along with providing essential support services. Demand in this sector can fluctuate due to changing civil developments and emerging trends, such as autonomous vehicles and space travel.

Challenges include geopolitical disputes, environmental calamities, and economic slumps, which can impact investment and growth in aerospace engineering. As technology evolves, the industry must adapt to advancements like sustainable aviation practices and the integration of artificial intelligence in design and manufacturing processes.

Regulatory compliance is critical, as organizations must follow strict safety and security regulations that govern aircraft design, production, and maintenance. Adhering to these standards is vital to avoid severe consequences, including fines and reputational damage.

An Overview of Automotive Industrial Manufacturing

In the rapidly evolving automotive manufacturing industry, change is a constant factor driven by consumer preferences, regulatory developments, and evolving industrial manufacturing solutions. Economic fluctuations also influence the types of vehicles that consumers seek. Automotive manufacturers must remain agile, relying on real-time data to inform their decisions. A critical tool for achieving this agility is a PRM program.

PRM technology addresses key challenges faced by manufacturers, such as the growing complexity of vehicles and the need for cross-departmental collaboration from the initial concept to market launch. As consumer demands shift, various teams—including engineering, design, finance, marketing, and sales—must adapt quickly to remain competitive.

Product roadmaps offer comprehensive visualizations of the product life cycle, illustrating dependencies and priorities while clarifying each department's role in achieving broader business objectives. By ensuring that all team members have access to real-time data, PRM technology helps prevent duplications and mistakes in the manufacturing process.

Top 8 benefits of PRM

PRM serves as a strategic framework that guides teams in navigating the complexities of product development. Here are its benefits:

1. Goal alignment

Strategic alignment is crucial, as individual teams can become so absorbed in their technical tasks that they lose sight of the overall objectives. However, manufacturers utilizing product roadmap management (PRM) tools can maintain focus on broader strategic goals, including manufacturing excellence. By keeping all teams aligned with a unified set of objectives, PRM tools provide direction and a shared purpose, helping to ensure that day-to-day activities support the company’s larger vision.

2. Distribution of resources

A product roadmap provides a clear view of future projects, allowing manufacturers to better forecast their requirements. This enables more efficient use of R&D funding, supplies, staff hours, and infrastructure. Roadmaps help avoid excessive use and waste, keeping projects streamlined and on budget. For automotive and aerospace manufacturers, they support forward planning and effective utilization of resources, from funding to workforce, acting as a safeguard against over-commitment and inefficiency.

3. Risk mitigation

Risk is an inevitable part of any large manufacturing initiative. Manufacturers can better forecast challenges by offering a more comprehensive outlook on upcoming projects and devising strategies to address or avoid them, greatly lowering risk exposure. While every industry faces risk, automotive and aerospace manufacturing can be particularly unpredictable. Fortunately, PRM enables these industries to foresee problems, helping them plan manufacturing solutions and mitigate risks before they escalate.

4. Streamlined communication

It's common for various teams to operate independently, but aligning with a unified framework can greatly enhance communication, both inside and outside the organization. Effective PRM tools allow manufacturers to share crucial data with external partners, such as shareholders or governing bodies. Automotive manufacturing capabilities rely on collaboration between departments like marketing, supply chain management, design, and engineering. Roadmaps promote seamless coordination, reducing friction and minimizing miscommunication throughout the development cycle.

5. Compliance with regulations

Product roadmaps help these industries to integrate all essential compliance guidelines and safety regulations into the creation process, minimizing the chance of violations during the product's lifecycle. Additionally, automotive products must undergo endurance tests, mechanical tests, thermal cycling tests, and maintain a product life profile to meet stringent regulatory standards. These roadmaps usually outline timelines and strategies for ensuring adherence to safety and emissions requirements, among other regulatory obligations.

6. Deadline management

Aerospace and automotive manufacturers frequently contend with various schedules, managing several products, each at distinct phases of development. Product roadmap technology enables these manufacturers to effectively track timelines and critical deadlines, ensuring clarity while monitoring progress toward key milestones. Monitoring deadlines is crucial in these industries as it helps prevent costly delays, ultimately leading to successful and timely product launches while maintaining a competitive edge in a rapidly evolving market.

7. Performance assessment

PRM tools incorporate essential performance metrics, such as key performance indicators (KPIs) and benchmarks, which assist aerospace and automotive manufacturers in monitoring their progress and assessing overall success. By utilizing these metrics, teams can make necessary modifications to their products, ensuring they meet all project objectives. Measuring KPIs is crucial in the automotive and aerospace industries as it provides insights into efficiency and, ultimately driving innovation in these high-stakes markets.

8. Market agility

Product roadmaps empower manufacturers to strategically plan for the future, allowing them to foresee and adapt to various changes in the marketplace. These shifts can be evolving consumer tastes, technological advancements from competitors, economic fluctuations, regulatory updates, and emerging market trends. By adopting a proactive approach, manufacturers can effectively introduce novel models that align with current market demands, ensuring they remain relevant, fostering business growth and resilience.

Bottomline

Product Roadmap Management (PRM) plays a crucial role in the aerospace and automotive industries by offering a structured approach to navigating the complexities of shifting technologies. As these sectors advance, PRM promises to facilitate the integration of innovative solutions and emerging trends, ensuring that manufacturers can meet future challenges and capitalize on new opportunities in the market.

As one of the Top 20 EMS companies in the world, IMI has over 40 years of experience in providing electronics manufacturing and technology solutions.

We are ready to support your business on a global scale.

Our proven technical expertise, worldwide reach, and vast experience in high-growth and emerging markets make us the ideal global manufacturing solutions partner.

Let's work together to build our future today.

Other Blog