Top 6 Challenges for Manufacturing in 2024

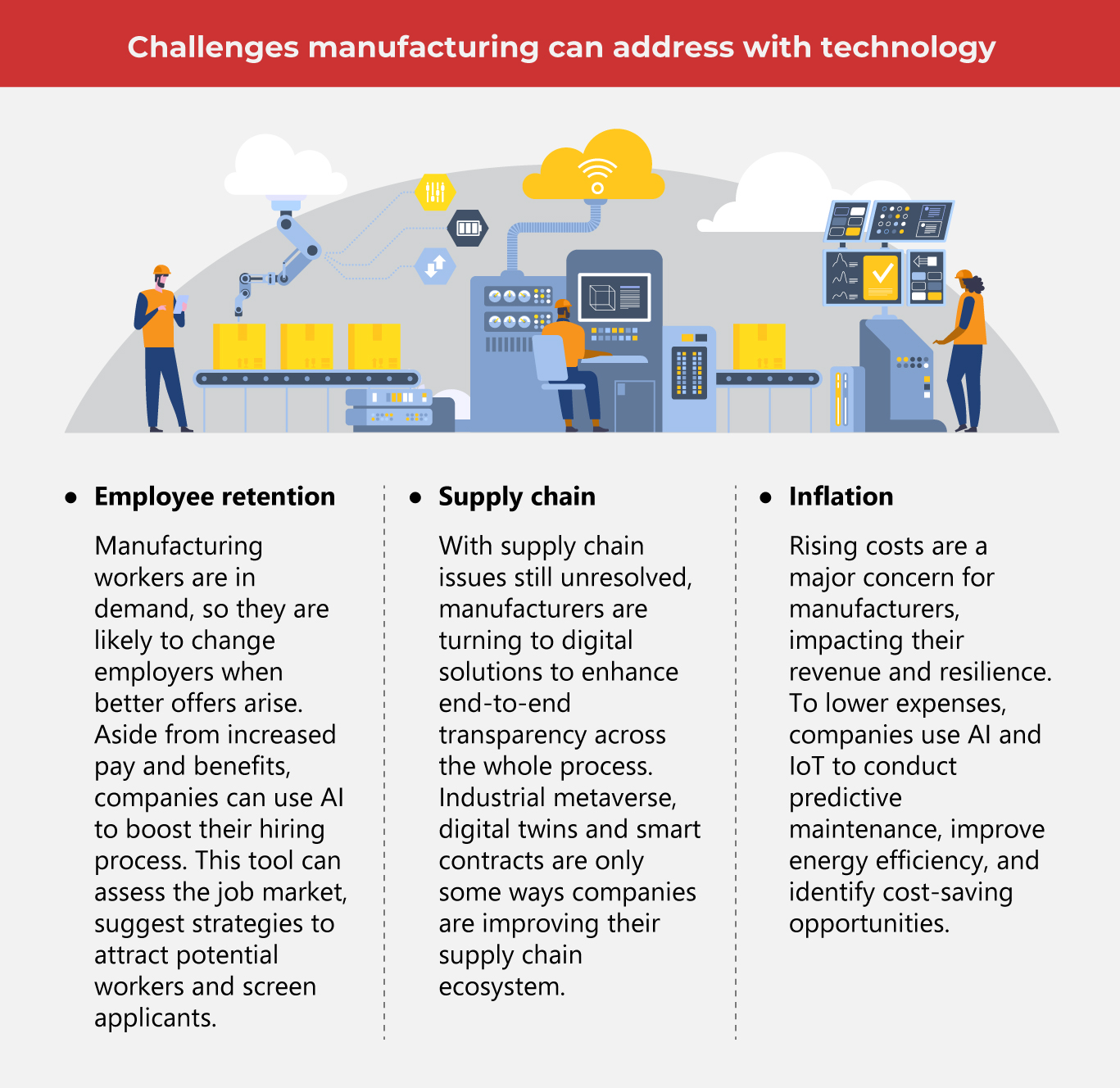

The global manufacturing industry has its lion's share of disruption due to the pandemic, supply chain issues, rising costs, and international conflicts. Companies have adopted technologies and other innovative measures to shield their businesses from unpredictability. As a result, smart manufacturing emerged, marking the beginning of a new industrial era.

Allied Market Research predicts the global smart manufacturing market to expand to US$860 billion by 2031, displaying a CAGR of over 13%. In connection with this, Statista forecasts the manufacturing industry to grow by 3.6% yearly until 2028.

There's no doubt that manufacturing growth and technological advancements go hand in hand. New technologies boost the industry and vice versa, so manufacturers are optimistic about the coming year despite the overwhelming challenges. According to a Wipfli survey, 88% of its participants look forward to more earnings in 2024. To do this, business owners plan to attract new customers and boost revenue from current markets. This optimism reflects their confidence in overcoming past challenges while maximizing new opportunities in today's digital era.

Top 6 tech challenges to conquer in 2024

The coming year finds manufacturing businesses adopting smart technologies, which bring industrial manufacturing solutions and challenges. Here are some difficulties manufacturers can expect as they make the high-tech transition.

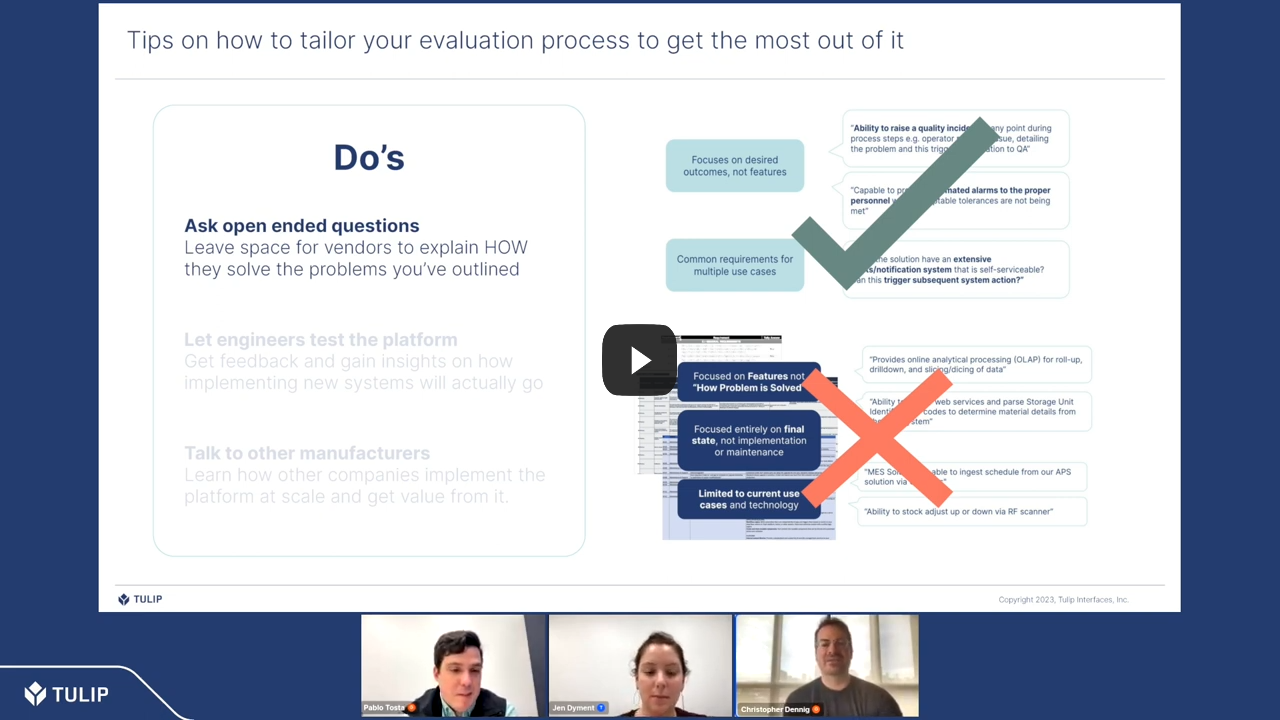

1. Choosing priorities

With so many applications promising business transformation, manufacturers should take some steps to ensure a smooth transition. Assessing business goals, current manufacturing processes, industry trends, and budget constraints can help their decision-making. But compounding this challenge is technology's rapid evolution, which makes it difficult for businesses to keep up. Some manufacturers never move on from the analysis stage, resulting in business paralysis. The solution lies in finding reputable suppliers and solutions that offer flexibility. These products should promote quick adoption, compatibility with existing systems, and scalability.

2. Commitment to digital transformation

The Wipfli survey reveals that 99% of manufacturers think digital innovation should be a priority, but only 47% have utilized automation or robotics. This speaks of the untapped potential that business owners hope to finally harness, with 71% of respondents planning to expand tech investment in 2024. Though digital transformation is daunting, it remains an important way to handle current manufacturing issues while ensuring business resilience and competitiveness.

3. Accelerating AI integration

Artificial Intelligence (AI) offers many benefits—from product design and development to work efficiency and supply chain management. However, AI adoption requires large amounts of relevant data, which may be difficult in manufacturing. Other hurdles include the diversity and complexity of manufacturing processes and supply chains, labor gaps, and additional technologies, training, and infrastructure costs. Because acquiring AI needs a significant initial investment, some manufacturers may be concerned about return on investment (ROI). This is why it's vital to consider the costs with the expected benefits.

4. Adopting a smart factory

AI is part of establishing a smart factory. But there are many more solutions to integrate, like the Internet of Things, digital twins, cloud computing, and data analytics. All these combined create an environment conducive to real-time and actionable information, a complete production overview, and adaptable solutions. Its benefits of boosted efficiency, better product quality, lower expenses, and more are why the smart factory market is pegged at over US$321 billion by 2032, with a 9.52% CAGR growth from 2023. Meanwhile, a Deloitte study indicates that 86% of those surveyed see smart factory solutions driving business competitiveness over the next five years.

Another tech trend poised to take off is establishing an industrial metaverse, which combines several technologies to develop a 3D virtual environment. This allows smooth communication among global stakeholders, fast-track product development, and enhances customer experience. According to Deloitte, 92% of survey participants are already testing at least one use-case for the metaverse.

5. Sustainability

It's no secret that the manufacturing industry uses a lot of energy. There are various ways to optimize resources, and it's crucial to identify the areas and processes where energy can be better managed.

Governments are also contributing to a sustainable future by investing in the decarbonization of industrial manufacturers' products. For instance, the USA's Infrastructure Investment and Jobs Act (IIJA) has funded electric vehicle charging stations. At the same time, the Inflation Reduction Act (IRA) contributed to over US$270 billion in investments in incentives that promote clean energy.

For companies, the challenges lie in technical preparedness, significant costs of transitioning to emission-free measures, and promoting a circular economy for their products.

6. Data protection

Automation brings about many benefits but also leaves systems at an immense risk: cyberattacks. According to Wipfli, 35% of respondents experienced at least three incidents of unauthorized data access in the last 12 months. However, this figure is already improving, mainly because 70% of manufacturers increased their spending on cybersecurity.

Business owners should prioritize data protection and high-value projects to mitigate these risks. Though ROI is an important consideration, cybersecurity technologies are just as vital, protecting company resources, supply chains, and confidential data. Numerous companies use various strategies to detect, oversee, take steps, and participate in scenario planning to improve their data security.

Vision and proactiveness are essential tools in business resilience. Manufacturers should acknowledge the benefits of smart factories and utilize them to streamline operations and stay competitive. By leveraging these trends, companies can be industry frontrunners while helping shape the field's development.

As one of the Top 20 EMS companies in the world, IMI has over 40 years of experience in providing electronics manufacturing and technology solutions.

As one of the Top 20 EMS companies in the world, IMI has over 40 years of experience in providing electronics manufacturing and technology solutions.

We are ready to support your business on a global scale.

Our proven technical expertise, worldwide reach, and vast experience in high-growth and emerging markets make us the ideal global manufacturing solutions partner.

Let's work together to build our future today.

Other Blog