Top 10 EV Battery Innovations This 2023

What will power the electric vehicle (EV) industry in the future? It depends on how EV batteries will be developed, boosting energy efficiency, affordability, and performance.

According to the United Nations, the transport segment is the biggest contributor to greenhouse gas emissions for 45% of countries. For the rest of the countries, it's the second largest source of carbon pollutants.

But more and more consumers are aware of this alarming fact. The International Energy Agency reports that the number of electric vehicles (EVs) sold doubled in 2021 and continued to show a solid sales performance in 2022. Meanwhile, transport experts predict these figures will continue accelerating, resulting in EVs comprising one in four passenger cars sold by 2030.

Still, battery innovations will drive the widespread adoption of EVs. Organizations worldwide are racing to create the best batteries to convince motorists to switch to the more eco-friendly EV.

Also read: Our EV Future: The Road So Far

Top 10 EV Battery Trends

Researchers and carmakers are making promising progress in formulating solutions to fulfill consumers' needs better and improve the EV. Despite challenges, innovators persist because transitioning to carbon-free transportation has become crucial. Here are some trends that have been making waves in the industry.

- Lithium-air batteries

Unlike lithium-ion batteries which use liquid electrolytes, this version uses solid ones, increasing power by as much as 400%. With this boosted energy comes a longer driving distance–plus improved safety because it prevents overheating and fire incidents, which are risks of Lithium-ion batteries.

As its name suggests, lithium-air batteries use air, particularly oxygen, from their surroundings. While previous models of this product showed poor longevity, the new design has been tested for a thousand charging cycles, proving its reliability and durability.

- Lithium ferrous phosphate batteries

Nickel and cobalt are material mainstays in most EVs in Europe and the US. But these metals are expensive, while cobalt mining has sparked controversy because of its unsafe working environment. Enter lithium ferrous phosphate (LFP) batteries which do away with these materials, providing a more affordable alternative.

Aside from being about 20% more cost-effective, LFP has faster charging speeds, letting EVs cover longer distances. It's no wonder that the LF market has grown to almost 40% in less than five years.

However, LFP is chunkier and tends to be on the heavy side. This is a major issue for EVs because they need more energy to carry the extra weight.

- The proliferation of battery plants

The government's participation has helped fuel the establishment of battery plants. In 2022, the US federal government shelled out around US$200 million to help a company build its Missouri factory, which manufactures LFP cathodes for EV batteries.

American Battery Factory, which is based in Utah, announced its plans to build a manufacturing plant for LFP batteries in Arizona by 2026.

But one of the biggest LFP-related projects so far is automaker giant Ford's LFP plant in Michigan, which starts production in 2026. Ford's EVs will use these batteries, which aim to be faster and pocket-friendlier.

- Less charging time

Time is gold, so innovators are targeting fully charging EV batteries in the least possible time.

In Japan, a company uses Ryden dual-carbon technology, which lets batteries power up 20 times faster than traditional batteries. The Spanish company Grapheno is developing an EV battery that can be charged in a few minutes but run for 500 miles. Meanwhile, a start-up based in Switzerland has developed a technology that charges EV batteries in just over a minute.

- Carbon nanotube electrodes

Nawa Technologies, a French company specializing in nanotechnology, produces a unique electrode that increases the battery's energy density by 300%. This translates to more power, battery longevity, and faster charging. According to the company, five minutes of charging can already give batteries up to 80% of charge. It's an exciting development, not only for the EV industry but also for the future of air and space travel.

- Lithium salt

As previously mentioned, lithium-ion batteries run the risk of catching fire. Because safety is always a priority, especially in the transport industry, scientists have formulated an electrolyte that can withstand extremely high temperatures of over 200°F. This is due to the additional lithium salt stabilizing the electrolyte's flammable molecules.

- Batteries integrated into the EVs

Chalmers University of Technology in Sweden has been developing new technology that makes batteries part of the EV's structure. Imagine batteries as car parts instead of separate components, making vehicles much lighter. This is done by using carbon fiber and lithium-iron phosphate, which respectively proved the negative and positive charges.

- Eco-friendly alternatives

The purpose of EVs is to make transportation environmentally friendly, so it makes sense for their batteries to aim for a low carbon footprint.

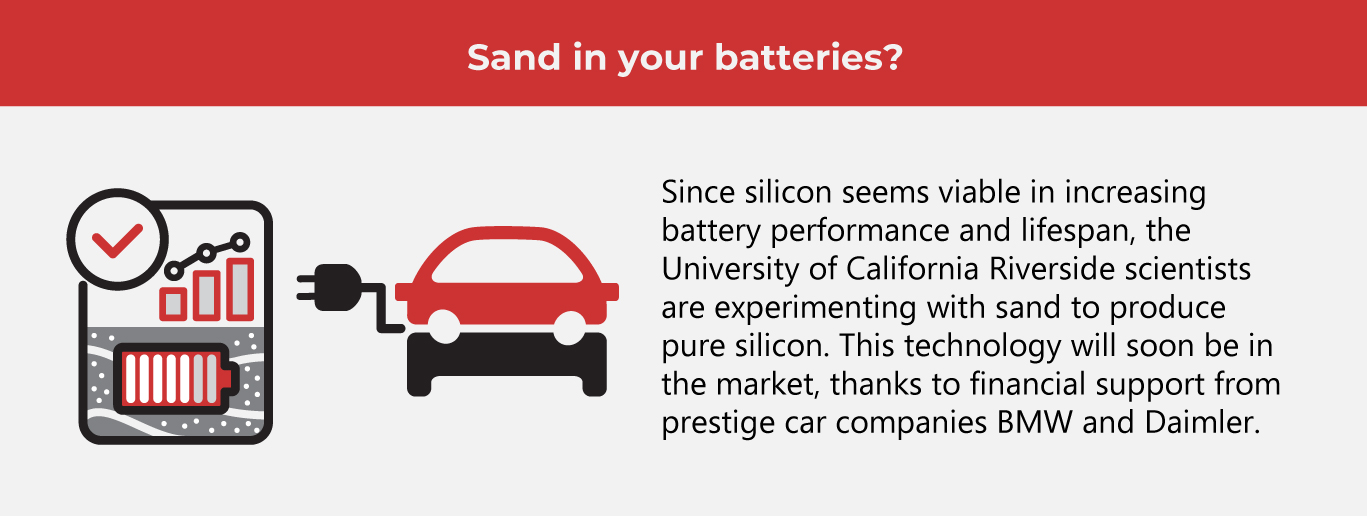

The University of Texas and China-based SVOLT are developing cobalt-free batteries that don't scrimper performance and power. Meanwhile, the University of Eastern Finland is focusing on eliminating the use of graphite as the battery's anode. Instead, they're using ten times more effective silicon produced from barley husk ash.

Also read: Silicon Carbide: Powering the Future of EVs

- Seawater as battery material

Luxury vehicle brand Mercedes-Benz has partnered with IBM Research to design novel battery chemistry that utilizes seawater. Another plus is that the battery doesn't use heavy metals but can still surpass the performance of lithium-ion batteries. According to IBM, seawater batteries allow faster charging and are cheaper.

- Alternative charging methods

Instead of plugging your EV in charging stations, innovators are exploring wireless methods. US-based uBeam transforms energy into sound waves transmitted to EVs. The company is harnessing this technology for laptops and mobile phones. Meanwhile, some researchers are exploring the possibility of collecting radio waves through an antenna that can be used to recharge EVs. With such developments, charging via Wi-Fi may soon become a reality.

As one of the Top 19 EMS companies in the world, IMI has over 40 years of experience in providing electronics manufacturing and technology solutions.

We are ready to support your business on a global scale.

Our proven technical expertise, worldwide reach, and vast experience in high-growth and emerging markets make us the ideal global manufacturing solutions partner.

Let's work together to build our future today.

Other Blog