Industries and the Race to Net Zero

The urgent challenge to reach carbon neutrality has added a lot of pressure on major industries worldwide. What real changes do these companies need to make to achieve their goals?

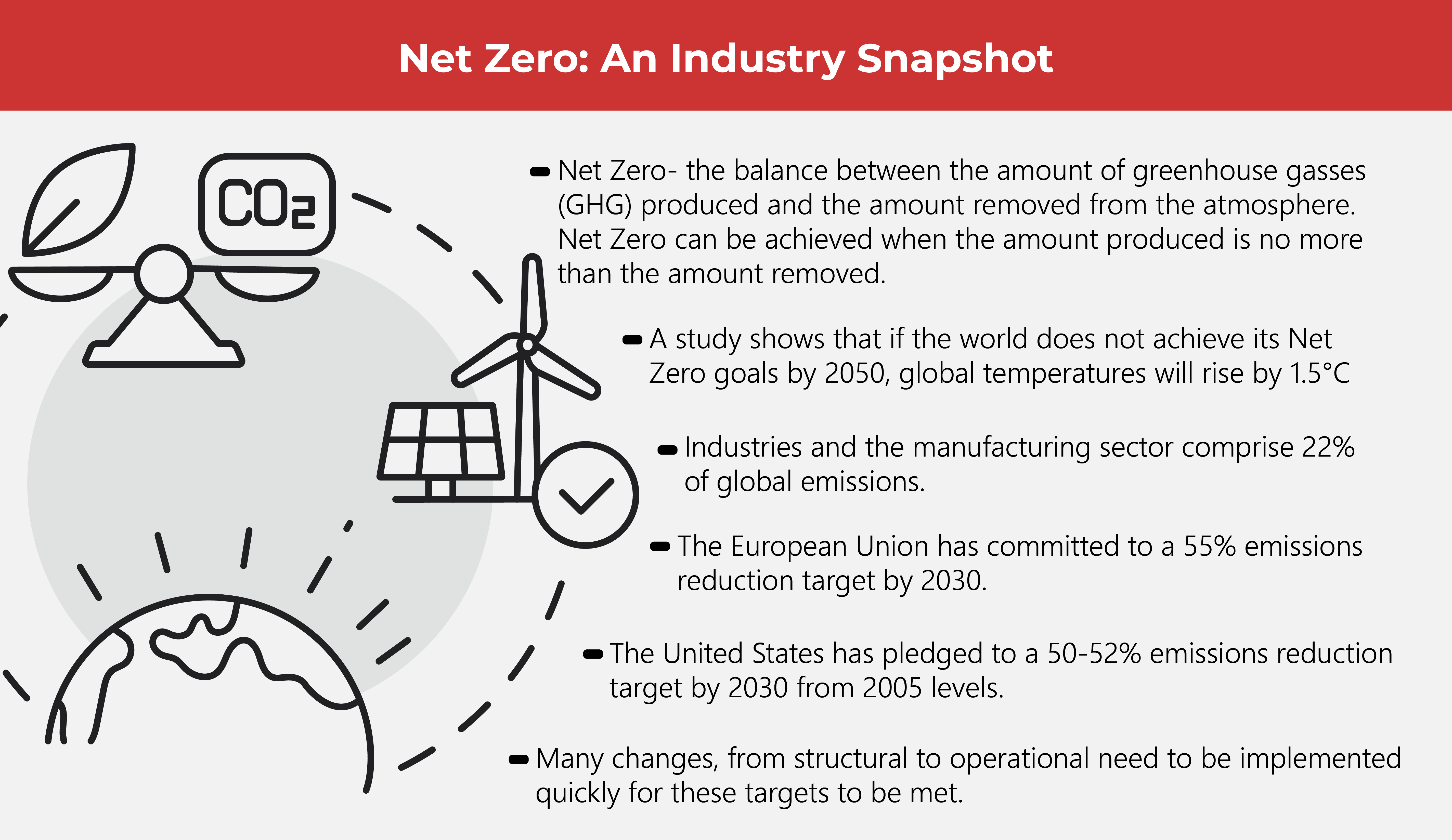

Targets to reach Net Zero by 2050 have been set, and industries around the world have been feeling the pressure to keep their end of the commitment made to reduce global carbon emissions. Major industries such as manufacturing, OEM, food and beverage, and construction contribute as much as 22% of global emissions, putting the onus of reducing greenhouse gas emissions (GHG) squarely on these companies.

Big changes are needed, and they need to happen now. This urgency combined with drastic consequences has pushed many of these companies to reflect, review, and re-evaluate the way they conduct business. For companies to meet Net Zero, it will require a lot of real effort from everyone involved from the top down, and across their supply chain.

Teamwork Makes The Dream Work

In an article presented in the Davos Agenda at the World Economic Forum, the CEO of a German food and beverage company, Stefan Klebert showed how manufacturing businesses can become carbon-neutral. Along with concrete steps on how to achieve this, a case study was shared of a successful company that has adopted carbon-neutral solutions.

Manufacturing companies are faced with the gargantuan challenge of carbon neutrality while also aiming to keep their businesses economical and profitable. While these goals may seem counter to each other, some industry leaders say that it doesn’t have to be, for as long as everybody is on board with the concepts and the real steps needed to take to achieve these. In short, teamwork.

(Also Read: Carbon Free Roads: Will Nations Hit Their Targets?)

In reality, “teamwork” needs to be broken down in terms of business approaches, structures, and operations. It takes more than just an ideal and elbow grease to make Net Zero happen, and a few industry leaders weigh in on what exactly is needed to make this dream work.

Operationally, companies are strongly encouraged to focus their collective efforts on increasing energy efficiency to reduce carbon emissions. Leaders urge their counterparts and colleagues to look around them and optimize existing technology they already have but to shift the way things are run.

From designing plants and work floors along with processes to reduce carbon emissions, to adopting heat pump technology to make the most of energy in processing, to deploying better practices, industry leaders are sharing knowledge, insights, and ideas that can be applied to any company serious about their Net Zero commitments.

A large-scale carbon neutral juice company shows what’s possible

The Blender, a juice company based in the Netherlands was able to prove these points, becoming the world’s first carbon-neutral juice plant. The Blender has set the bar for other food and beverage manufacturing companies. If they can do it, surely others can, too.

The Blender’s plant was able to prove that a large-scale manufacturing process is possible with existing technologies in place, keeping in mind three key priorities to operate: keep carbon emissions low by reviewing heating and cooling practices, and forging closer customer relationships. When their core customers became aware of what they were doing for the environment, business got better.

These days, we are more aware of the role companies play in global warming, and we want accountability from the companies and brands we support. It’s easier for the general public to support and buy from companies that are making real efforts to do their fair share in reducing their carbon footprint.

Other Steps to Carbon Neutrality

Apart from maximizing existing technology, especially concerning heating and cooling processes, industry leaders are looking into making greener, smarter business solutions and improving their industry standards. Standards governing bodies such as the BSI that audit and certify business systems management are instrumental in supporting these. A business that acquires certification is more likely to win new business.

A great example of this is Volvo. The OEM’s commitment to reducing carbon emissions has extended not only to car exhaust emissions, but now includes electrification, recycling, and the reuse of materials. The willingness to innovate and re-create if needed is essential to stepping up the Net Zero game.

Enterprise data analytics strategy is also one major tool leaders are looking into to strengthen the shift to more carbon neutral practices. This is important because this helps industries understand their carbon footprint in measurable ways, as well as the impact this will have on their products and services. Based on these measurements, leaders can make better decisions to meet goals and meet their financial targets as well.

While engineering, technology, and even business strategy have a lot to contribute to reducing carbon emissions, all of these must be supported by a drastic change in the business outlook. Prioritizing what’s right and best for the environment is not easy, and neither will it be cheap for these companies, but if they are determined to do their part, then the industry needs to put Net Zero first and greed a distant second.

As one of the Top 19 EMS companies in the world, IMI has over 40 years of experience in providing electronics manufacturing and technology solutions.

We are ready to support your business on a global scale.

Our proven technical expertise, worldwide reach, and vast experience in high-growth and emerging markets make us the ideal global manufacturing solutions partner.

Let's work together to build our future today.