How OTEC Can Power the Future

Ocean Thermal Energy Conversion (OTEC) has existed for centuries but is only fully explored now as a renewable energy source. Researchers focus on maximizing energy extraction to boost OTEC's efficiency and potential as a reliable power supply.

According to National Geographic, the ocean comprises over 70% of the Earth's surface. About 97% of the planet's water supply comes from the sea, highlighting its role in shaping our temperature, weather, and food security. But scientists are also exploring the sea as a power source because of its nearly limitless nature, making it a promising component of global sustainability goals.

What is OTEC?

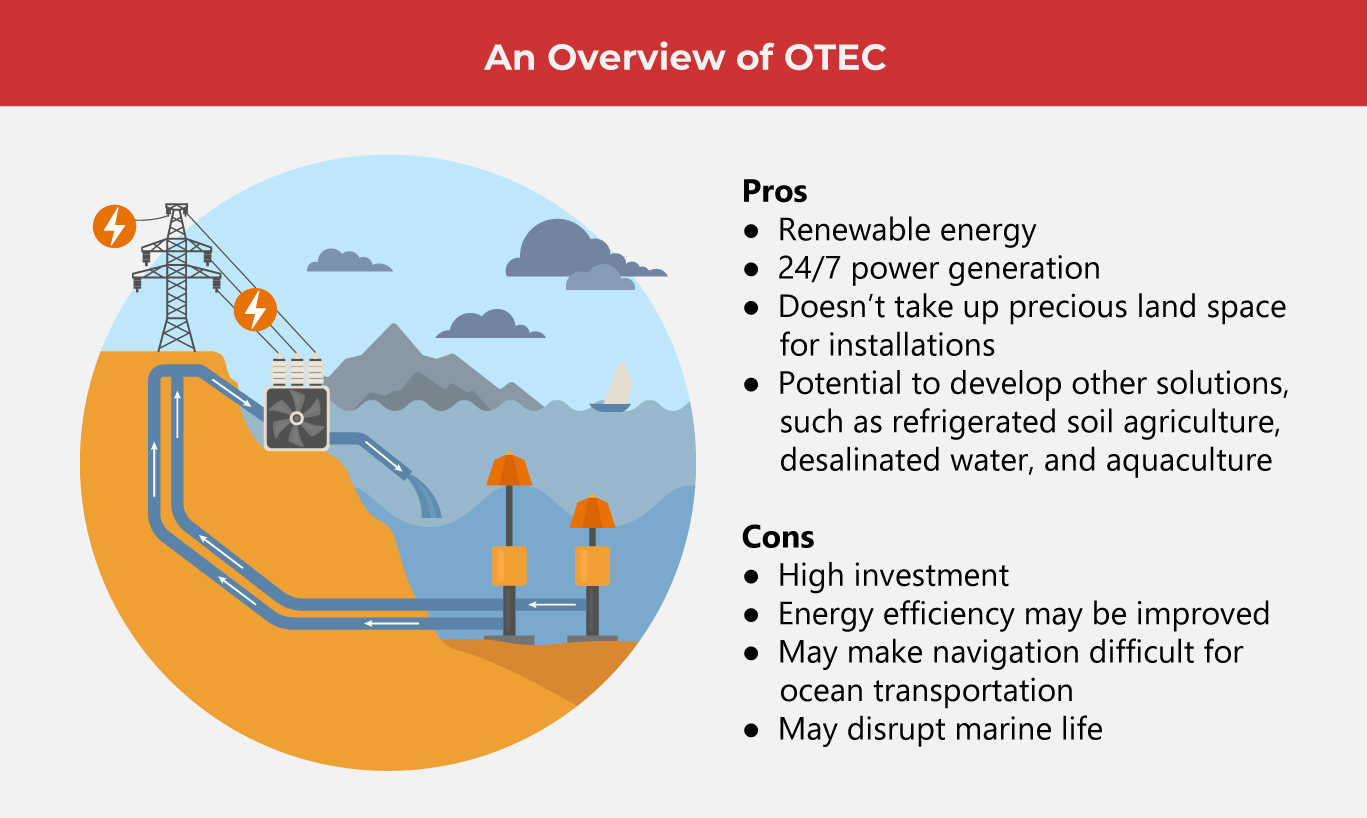

Ocean Thermal Energy Conversion (OTEC) produces renewable energy by leveraging the temperature contrasts in the ocean water—between its cold depths and sun-warmed surface. This technology applies to regions near the equator, wherein the thermal difference of at least 20⁰C (36⁰F) remains constant throughout the year. The collected power can be as much as three to five TW (terawatts) without damaging the ecosystem.

One needs vast volumes of cold and warm water to produce electricity. For instance, a 100-megawatt OTEC site typically needs at least a billion gallons of water daily. A cold-water pipe connected to the platform should be robust enough to endure the strain of a marine setting. To gather water with a temperature of 20⁰C, the pipe should have a width of 33 feet and reach a depth of 3,300 feet.

A platform on the ocean surface holds the equipment necessary for the OTEC structure, which can be seen from the shoreline. Dock lines and anchors secure this stable and fixed platform. Meanwhile, a power cable on or under the ocean floor would link the electrical grid to the offshore facility.

How OTEC works

An evaporator containing working liquid draws warm surface water, with the vapor or steam powering a generator. This is the Rankine cycle, a thermodynamic process wherein the heat input results in work generation. The cool water from the deep ocean condenses the liquid. To penetrate this depth, a power generation installation floats and operates about 10 kilometers from the shore. A cable conveys electricity to the floating platform from the shore.

Generally, four OTEC strategies have undergone theoretical and real-life experimentation.

1. Open-cycle

This technique is marked by a vacuum, a state that arises within an enclosed space when there is no air pressure. The warm surface water is pumped into a vacuum chamber at 1% to 3% of the atmospheric pressure. This pressure decline causes rapid water evaporation. Salt, seawater and other non condensable gasses, such as nitrogen, oxygen, and carbon dioxide, stay within the vacuum container, which means the vapor is composed of fresh water. The steam travels through a low-pressure linked to an electrical generator. Besides power generation, this method also yields desalinated freshwater, ideal for potable water, agricultural practices, and aquaculture.

2. Open-cycle with mist lift system

In this method, a hydroelectric turbine substitutes a steam turbine. It also uses a floating structure made from concrete—a significant portion of which is immersed in water. The turbine, situated at the structure's foundation, produces electricity. Vast quantities of warm ocean water, which descend from an elevation of 100 meters, power the turbine.

Mist lift systems are named such due to their use of the water-lifting method, wherein water is reintroduced into the top part of the structure. The warm surface water boils because of the semi-vacuum within the container, generating a significant volume of ascending steam. Chilled sea water streams falling at a 20-meter height are dispersed into the steam, rapidly condensing and resulting in a pressure drop. The pressure contrast between the structure's bottom and upper sections forces out a fine mist of steam in multiple phases.

3. Closed-cycle

With the closed-cycle OTEC system, the most significant expense is the heat changers, which relocate heat from one location to another. The first successful attempt of this system happened in Hawaii in 1979. Located over two kilometers off the shore, the setup generated enough power to operate a ship's lighting system and some electronic devices.

4. Hybrid cycle

This process merges features of closed- and open-cycle methods. After a vacuum rapidly evaporates the surface water, steam boils the working fluid. The refrigerant inside the turbine is expanded, generating electricity. Meanwhile, the vapor condenses within a heat exchanger, which produces desalinated water.

Where OTEC is heading

French physicist Jacques-Arsène d'Arsonval introduced OTEC in the 1880s, but it took 40 years before the closed-cycle OTEC technique was invented.

This approach is finally making headway, thanks to recent technological advancements. Global OTEC, a company based in the UK, is fast-tracking plans to build a 1.5-megawatt structure off Sao Tome and Principe by 2026. Another island nation site in the works is Fiji. The company aims to make these places self-sufficient in energy generation since they mainly import costly diesel from rich petrol-producing nations.

Challenges for OTEC

Though OTEC has numerous potential benefits, it must overcome these challenges to thrive.

- Safety

Comprehensive safety measures must be developed and monitored to secure the workers, especially for the mooring network and submerged electric cables. Operators must formulate emergency procedures in case of extreme environmental conditions. Offshore platforms must be stable, so researchers are experimenting with traditional anchorage systems, AI-assisted analysis, and pressurized tubes.

- Low energy conversion

The main reason for this challenge is the slight temperature variation between cold and warm seawater. Even in the tropical region, this amounts only to the required minimum of 20⁰C. Some recommend combining OTEC with other heat sources like solar energy to boost thermal performance.

- Financial feasibility

The technology requires infrastructure and equipment that developing countries may need help to acquire. For this reason, pilot OTEC systems below 300 kilowatts may not be cost-effective for low-income countries. Governments need to step in for OTEC to thrive.

There is no doubt that OTEC technology has great potential, given its sustainable energy source. Various entities are developing solutions and innovations to lower implementation costs and improve efficiency. To do this, different fields of expertise, such as engineering, thermodynamics, and novel materials, must work together. Only then can we generate a holistic perspective, optimizing OTEC to produce energy, fresh water, and food while promoting community development.

As one of the Top 20 EMS companies in the world, IMI has over 40 years of experience in providing electronics manufacturing and technology solutions.

We are ready to support your business on a global scale.

Our proven technical expertise, worldwide reach, and vast experience in high-growth and emerging markets make us the ideal global manufacturing solutions partner.

Let's work together to build our future today.

Other Blog