Entering Industry 5.0

The next phase of industrialization may already be upon us. Experts in the tech world are already calling it Industry 5.0.

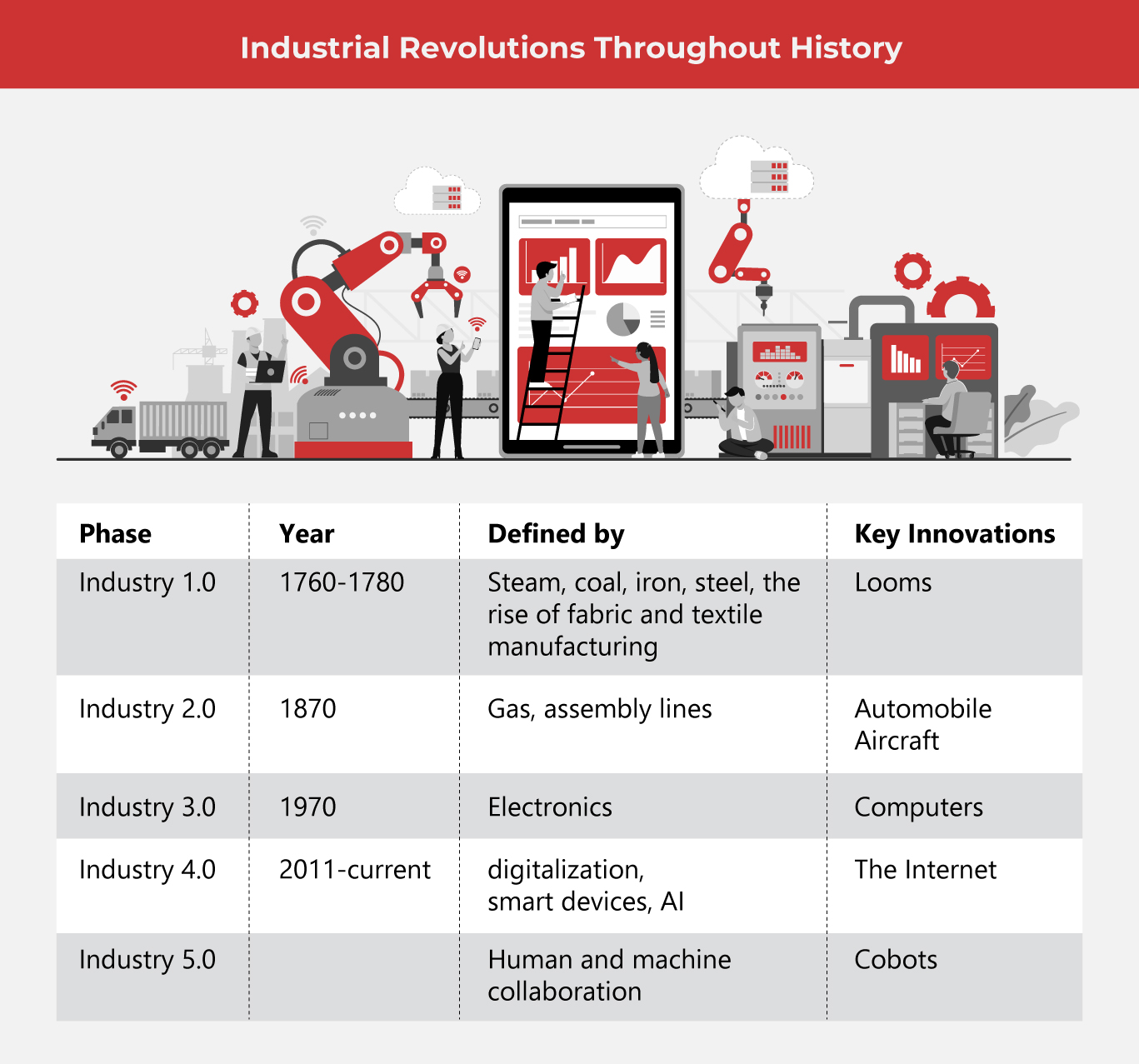

Artificial intelligence, big data, machine learning, the Internet of Things, and digitalization are all technologies that are defining Industry 4.0, or, the current industrial phase the modern world is in.

Just as businesses around the globe are pivoting to meet demands that put a premium on efficiency, connectivity, and optimization, here comes the next big phase. Are we ready to meet it?

Industry 5.0: The Basics

If Industry 4.0 concentrates on digitalization, machine learning, and robotics, what will the next phase bring?

(Also Read: The Rise of Cobots in 2023)

The European Union defines Industry 5.0 as “providing a vision of industry that aims beyond efficiency and productivity as the sole goals, and reinforces the role and contribution of industry to society.” Additionally, “it places the well-being of the worker at the center of the production process and uses new technologies to provide prosperity beyond jobs and growth while respecting the production limits of the planet.”

When experts unpacked what exactly this means, the takeaway was that Industry 5.0 is about humans and machines/robots working alongside each other. “Placing the wellbeing of the worker” might assuage worker apprehension of having machines and robots take over and replace them at their jobs, and instead recognizing that to take businesses to the next level, humans are very much still the secret ingredient to what makes the whole operation work.

Humans? Underrated, as Telsa CEO Elon Musk famously tweeted. Many other C-suite executives like him have learned the rather hard lesson that “too much automation” can be a mistake. Take out the beating heart and the thinking mind of a skilled human worker, and the whole thing could fall apart.

The emphasis on the human element working alongside a machine or a robot becomes one of the essential tenets of Industry 5.0. Robots are essential for repetitive tasks such as heavy lifting, allowing humans to focus on other tasks that “add value to the end user” i.e., other humans.

For example, the machine can process massive amounts of information such as algorithms that help determine a customer’s location, demographic, preference, and so on. The human can use the processed results to deliver the service or the product customers need.

This brings us to the next tenet of Industry 5.0, which gives rise to personalization. Richard Mount, an executive at Swindon Silicon Systems said that “hyperpersonalizing” or “mass customization” could be a benchmark for the next phase of the industry.

He says that while the term “mass customization” may sound oxymoronic, scaling personalized services or products may just be the direction we’re headed in.

If customization will propel new business models in the next phase of industrialization, then 3D printing and additive manufacturing will play a larger role in Industry 5.0, thanks to the new freedom in design it gives. The strict rules of manufacturing have now been smashed because 3D printing exists.

Businesses have the capabilities that allow them to cater to exactly what it is the customer needs, whether it be a streaming service experience, the latest mobile device, or a medical wearable.

As end users, we have become used to this as the default setting for almost everything man-made we come in contact with. We want things to do exactly what we want them to do in the ways we want them to. And when do we want them? Now.

Mount says manufacturing companies can “leverage the big data analytics to see purchasing patterns and demographic information so manufacturers can tailor products to meet individual needs.”

Because Industry 5.0 needs skilled human workers, it signals the creation and the demand for new sets of skills and talent for working alongside robots and machines. New roles will need to be filled, and new opportunities will be created. Jobs that did not exist five years ago may just be the next in-demand career.

A More Responsible Industry?

A shift in attitude marks the third tenet of Industry 5.0. It gives importance to sustainability. As Jeroen Kraaijenbrink says in his Forbes article, “It’s business as usual, but more responsible.” He’s not the only one who has noticed how radical a shift Industry 5.0 has taken in terms of what businesses need to pay attention to. Instead of efficiency and optimization, the focus has now shifted to “well-being” and “the limits of the planet”.

Does this mean that businesses have finally grown a conscience and are now putting doing the right thing at the core of how business is run? Sounds great.

As one of the Top 20 EMS companies in the world, IMI has over 40 years of experience in providing electronics manufacturing and technology solutions.

We are ready to support your business on a global scale.

Our proven technical expertise, worldwide reach, and vast experience in high-growth and emerging markets make us the ideal global manufacturing solutions partner.

Let's work together to build our future today.

Other Blog