Electronics Leaders Weigh In on Sustainability Challenges

What would it look like for the electronics industry if it were to become more sustainable?

E-waste is arguably the largest challenge the electronics industry has when it comes to reaching sustainability goals.

(Also Read: Diving into E-waste: Hard Facts and What You Can Do about It)

Financial Times drew a bleak summary of just how much e-waste was accumulated in a single year. Their data comes from a UN Global E-waste Monitor report from 2020, stating that in 2019, 53.6 million tons of e-waste were dumped worldwide, which would roughly be the same weight as “4,500 Eiffel Towers”. It’s a staggering figure, and the more we switch to newer models of electronic gadgets, the larger that number becomes.

The question being asked of the industry is: “Can it become sustainable?”

Leaders from the electronics industry are choosing to tackle the problem with teamwork.

The July 2023 edition of the IPC Community Newsletter featured the recently convened Sustainability for Electronics Council. The council is made up of leaders from the EMS, OEM, and PCB sectors from around the world.

Because the electronics industry is vast and covers numerous sectors, the IPC stands as a blanket association covering the entire industry, standardizing language, best practices, and industry benchmarks. Its Sustainability for Electronics Council was formed to steer the direction and offer peer review to associates, helping associates understand one another in the dialogue for sustainability.

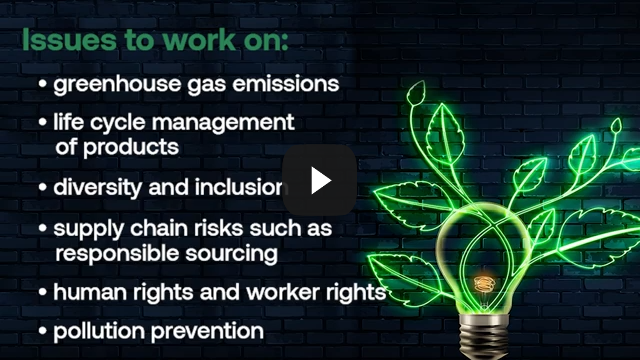

Part of the council’s goals is to serve as a rich resource for “proposing global efforts” that will improve sustainable design, development, and manufacture of electronic products. The industry leaders that are part of this council span various links in the supply chain and come from different global regions. They are senior members of their respective companies who are committed to upholding ESG programs.

Their goal for the year is this: to set a sustainability strategy roadmap that will serve as the industry standard for best practices, education, and advocacy.

Many of its members joined the council because they saw the value of coming together with peers to determine priorities, set essential steps, and find connections in the challenges their respective companies face to find viable solutions.

Says council member Barjouth Aguilar, minimizing their company’s environmental impact is a priority, and that their 2030 sustainability strategy focuses on doing just that. Inclusivity and fostering a safe working community are valuable in forging partnerships that allow finding solutions to reduce supply chain emissions.

Top of mind for her is materiality assessment. This will help the council determine areas of focus and create an assessment that reflects common industry as well as stakeholder priorities. Everyone working in alignment and being on the same page is vital to the council’s first steps.

Meanwhile, Stanley Merritt, head for an OEM catering to aerospace and defense, says that their position offers a unique and much-needed perspective to the IPC, “especially when it comes to supply chain best practices.” For him, data security and how it is maintained and communicated across the supply chain plays a large part in maintaining best practices.

“Sustainability, CO2 footprint, and emission reduction are important [to our company] and influence our company’s strategy,” says Marcus Ottrin, who comes from an EMS company. For him, interacting with counterparts from across many different global regions was key to his becoming a member of the council. He thinks that sustainability considers the entire lifecycle of a product. According to Mr. Ottrin, suppliers have 10-15% influence on the sustainability of a product, and in turn, OEMs have the biggest influence on these suppliers.

Lastly, council member Colin Cupitt keeps it simple. Their company’s sustainability agenda is to “serve, supply, and protect those who serve, supply, and protect us.” He sees supporting government sustainability initiatives such as national decarbonization programs as an important step in developing sustainable solutions.

For him, one of the council’s goals is to prime the electronics industry to be “better equipped to address the changing scope of sustainability”. Legislation is key to ensuring that the strategies will be implemented and that companies and their customers will be protected.

Like the IPC Sustainability for Electronics Council, the Circular Electronics Partnership (CEP) has similar goals. CEP brings together leaders from technology, consumer goods, and waste management”. Formed in 2021, their goal is to re-think and come up with better designs to support a circular economy.

An industry expert said that circular economy “doesn’t just happen.” No one person just decides to do it. It must be a concerted effort that comes from the top and trickles down to the entirety of the value chain. This includes the end user, who also has a large role to play when it comes to sustainability.

CEP’s manager, Caroline Van Brunshot says that consumers need to actively take part in the circular economy. A mindset that is attuned to using a product “for as long as you can” is essential. When something can no longer be used, “tear it apart and see what else it can be used for.”

In our modern world, upgrading our devices is a cycle many go through every few years. Replacing our mobile phones with the latest models, buying new laptops when our old ones no longer perform as they used to, and simply trying out the newest gadget for style reasons contribute to a normalized “upgrade culture”. Ms. Van Brunshot says that this is incompatible with a circular economy.

As consumers, our sustainability challenge is in making products last even when they’re not designed to last. We are encouraged to recycle and upcycle as much as we can to reduce e-waste. In support of the consumer initiative, many companies offer incentives when old models of their electronic gadgets are surrendered back to the company for recycling.

Thought and industry leaders coming together to align values and create a viable strategy to address sustainability issues can hopefully speed up new designs that make a circular economy a more easeful reality. “It’s not going to be an overnight shift,” Van Brunshot says. “It’s a gradual shift. But it’s happening.”

As one of the Top 20 EMS companies in the world, IMI has over 40 years of experience in providing electronics manufacturing and technology solutions.

We are ready to support your business on a global scale.

Our proven technical expertise, worldwide reach, and vast experience in high-growth and emerging markets make us the ideal global manufacturing solutions partner.

Let's work together to build our future today.

Other Blog