Boost Your Business with Robotics This 2024

Manufacturers need help with difficulties impacting their capacity to fabricate, deliver and sell goods that meet customer demands. All these challenges compel businesses to adopt automation and robotics.

A dire prediction: over 80 million jobs will be left vacant by 2030, of which 10% is in the global manufacturing industry. Such a huge labor gap can't be bridged overnight, so companies must formulate new strategies to beef up their workforce. To facilitate continued business growth and resilience, industries are turning to robotics and automation. Here are some reasons why these technologies are considered new industry captains.

- Healthcare

Automation is perfect for routine tasks like data entry and disinfection, freeing up healthcare employees for more crucial aspects of patient treatment. Meanwhile, robotics can assist in surgery, diagnostics, rehabilitation and other medical areas, ensuring precision and speed—both critical elements in this field. These technologies also enable remote patient care, automated medication dispensing, and early detection of diseases.

- Logistics

Robotics and automation enhance efficiency in warehouse management, thanks to technologies like Autonomous Mobile Robots (AMRs) and Automated Guided Vehicles (AGVs). These automate various tasks such as picking, sorting, and delivery. Monitoring systems can manage inventory, while data analytics can help business owners predict equipment maintenance and consumer demand patterns.

- Space exploration

Humans can only go so far in space travel. Where it's unsafe for them to go, robots and automated systems like planetary rovers can take over, exploring surfaces and collecting data. Unlike humans, these robots can tolerate extreme conditions and harsh environments. Automation is also vital in assembling and maintaining spacecraft and complex equipment, while autonomous navigation technologies help keep missions safe.

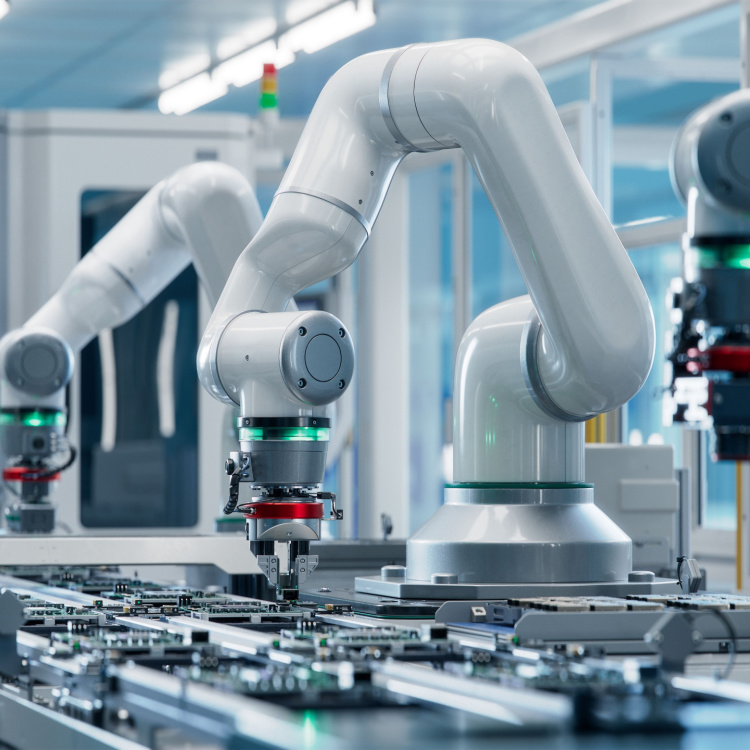

- Manufacturing

This sector was the first to adopt robotics and automation since industrial robots can complete routine tasks with speed and accuracy. Robots are especially useful in manufacturing tasks such as welding, assembly, and packaging. Manufacturing automation technologies help manage and direct robotic activities, enhancing their efficiency.

- Travel

Airports have streamlined their processes through self-service counters and automated baggage check-ins—measures that have boosted customer convenience while reducing delays. Security checks are more comprehensive and efficient, thanks to automated systems. Chatbots and virtual assistants improve customer service by giving fast assistance and real-time information. Other contactless technologies ensure smooth travel for passengers.

Pros of automation and robotics

Business resilience has become a measure of success due to recent global shifts, including those induced by the COVID-19 pandemic. New uncertainties abound, including geopolitical conflict and recently enacted laws. With these, robotics and automation systems have adjusted, being able to expand fast and scale down when conditions are unfavorable. Here are more advantages that urge businesses to jump on the automation bandwagon.

- Optimized efficiency

Business operations involve a diverse range of tasks, machines and protocols. Ample training time for employees is crucial to minimize errors and downtime. However, this is fine with industrial robots, which, after programming and installation, can go to work right away. These machines can work round the clock, improving speed and productivity while automation ensures accuracy.

Additionally, robots can accomplish tedious and repetitive work nonstop, enabling employees to handle more complex work and add to their skills. Automation also cuts costs in various ways, including letting businesses keep their processes within their company without any need for outsourcing talent and offshoring.

- Better output

Product quality is all about precision and constancy, which industrial robots are programmed to provide. It's only human to get burned out, which may lead to mistakes, even when workers are determined to be vigilant. On the other hand, robots thrive in repetitiveness without any danger of fatigue and lack of focus, maintaining a consistent performance. Because of their automation-boosted accuracy, robots can complete tasks with fewer errors, resulting in maximized production time and resources.

- Ensured safety

Hazardous tasks, extreme conditions, and exposure to harmful elements put humans at risk. However, with advanced sensors and monitoring systems, hazards can be detected in real-time, letting workers address them swiftly. Robot-only areas and protective barriers can improve workplace safety, as well as automatic shut-downs and emergency protocols. In cleanroom and sanitary settings, robots can directly interact with the products, minimizing the risk of contamination.

- Improved adaptability

Industry trends, economic situations, and consumer demands constantly change, so businesses can't settle on one operational formula. Managers need to tweak products and processes often, which require staff retraining. However, automation allows robots to adapt to these changes quickly through reprogrammed software. Novel systems can even store various programs, enabling faster product design and development.

- Higher revenue

While robots can complete tasks of several workers, new technologies also let operators handle many machines simultaneously. These cut labor costs, energy usage, and production expenses, allowing companies to gain a faster return on investment (ROI). Reduced operating costs and lead times, plus output increase, lead to an overall revenue boost.

Cons of automation & robotics

There are always two sides to a coin. Though automating processes offers countless benefits, business owners should also know its downsides. This helps them better prepare for risks, letting them fully reap the advantages of tech advancement.

- Worker displacement

Workers often fear being replaced by robots, which is true in some settings, like assembly lines. Managing employees whose jobs were taken over by automation can be challenging. Options employers can take are reskilling and retraining, career counseling, and flexible work arrangements. The solution lies in adopting a compassionate and comprehensive approach, allowing managers to maintain a positive work environment.

- Substantial upfront cost

Transitioning to robotics and automation requires a considerable investment. Some business owners may hesitate to shell out millions of dollars for a customized system that involves only a part of their production process. Maintenance costs of automated machines are also generally higher than their manual counterparts. This is why companies need to think long-term—that though they'll be spending a lot now, the eventual returns can exceed their initial investment.

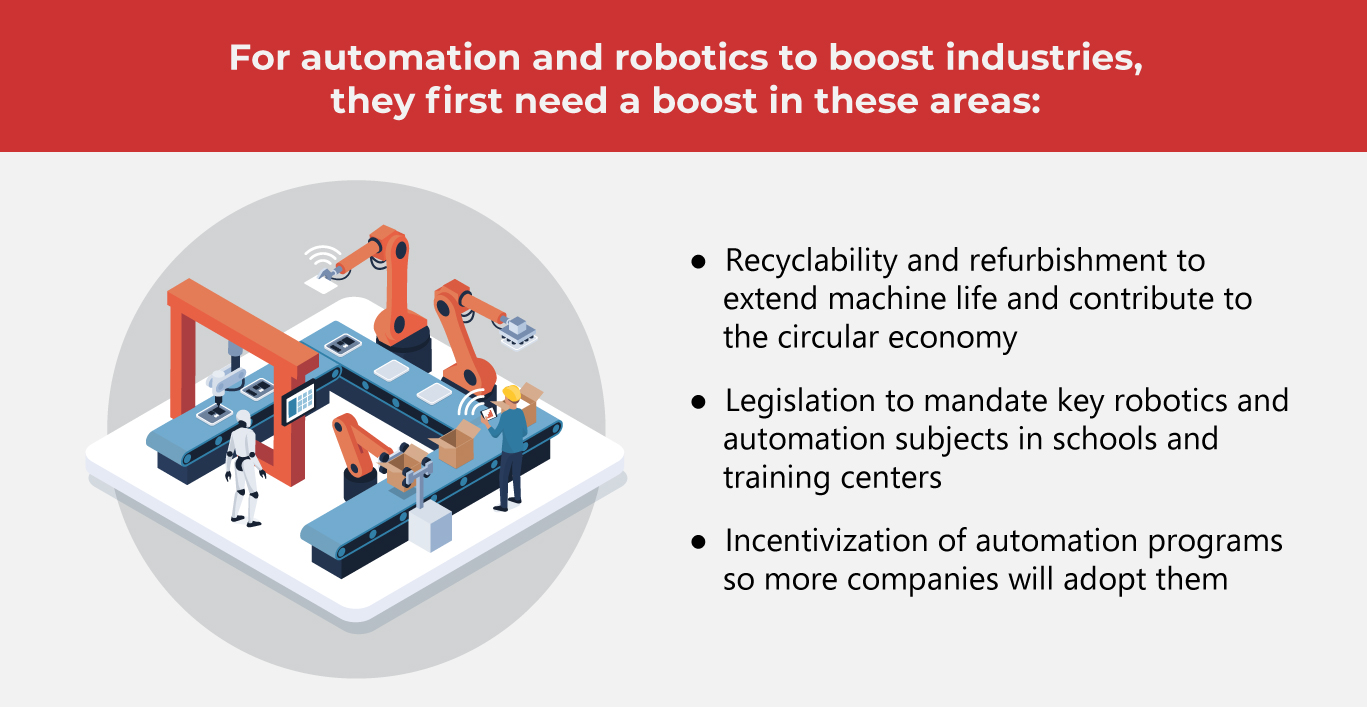

- Limited expertise

The automation industry may be rapidly growing, but experts in this field are hard to find. A lack of education and the high demand for tech experts across all industries are possible factors. Usually, original equipment manufacturers (OEM) train the company staff on how to operate and maintain automated systems, which increases costs and lead times. Also, some companies are averse to hiring professionals dedicated to automation, which stunts expertise growth.

- Technology constraints

Current robotics technology has come a long way, but it still has a long way to go. Many robots lack fine motor skills or intricate dexterity required in complex manufacturing processes. Moreover, some robots may be sensitive to environmental conditions such as heat and lighting, rendering them inoperable in specific situations. While AI helps improve machine autonomy, nothing beats human intuition, which deeply understands real-life dynamics. Robotics and automation may be revolutionizing industries, but ultimately, it shows the clear synergy between human understanding and technological innovation. Embracing these changes entails challenges, but it also offers benefits that improve resilience, ushering in a new era in the global economic landscape.

Robotics and automation may be revolutionizing industries, but ultimately, it shows the clear synergy between human understanding and technological innovation. Embracing these changes entails challenges, but it also offers benefits that improve resilience, ushering in a new era in the global economic landscape.

As one of the Top 20 EMS companies in the world, IMI has over 40 years of experience in providing electronics manufacturing and technology solutions.

As one of the Top 20 EMS companies in the world, IMI has over 40 years of experience in providing electronics manufacturing and technology solutions.

We are ready to support your business on a global scale.

Our proven technical expertise, worldwide reach, and vast experience in high-growth and emerging markets make us the ideal global manufacturing solutions partner.

Let's work together to build our future today.

Other Blog