AI and the Auto Industry: The Perfect Match This 2024

After escalating electric vehicle (EV) production, auto manufacturers are adopting the next big thing in the industry—artificial intelligence (AI). Learn how carmakers are leveraging this technology to boost features, manufacturing processes, and data analytics for the automotive industry to reach the next level of efficiency.

Auto companies are expected to invest US$74.5 billion in AI by 2030. This is no surprise, as the world's top auto manufacturers are incorporating AI into their products.

Volkswagen is integrating ChatGPT in its IDA voice assistant, enabling the feature to reply in detail to its driver's specific questions. This also allows IDA to better understand human needs and react accordingly to tasks such as finding a parking slot and providing on-the-spot route modifications.

Meanwhile, the BMW group revealed that its voice assistant will use generative AI through its partnership with Amazon. The Alexa large-language model (LLM) will power this new feature, facilitating more natural-sounding interactions and conversations between humans and machines.

Mercedes-Benz also utilizes generative AI in its MBUX virtual assistant, creating a personalized driving experience. The AI can memorize the driver's route and timetable through digital calendar access. It can also remind the driver of scheduled calls, even automatically placing them during the trip.

Sony has recently partnered with Microsoft to improve its Sony Honda Mobility. The company also leverages Vision Transformer, a deep-learning model that excels in processing natural language and recognizing images. With advanced driver-assistance systems, cars immediately identify and avoid hazards, significantly enhancing road safety.

10 Ways AI boosts the automotive industry's performance

Though more and more automotive industry players are adopting AI, most of their initiatives focus on virtual assistants. However, AI can play a much bigger and more dynamic role in vehicular manufacturing. From meeting quality standards to improving workforce experience, AI is fast becoming one of the most important technology trends in the automotive industry.

-

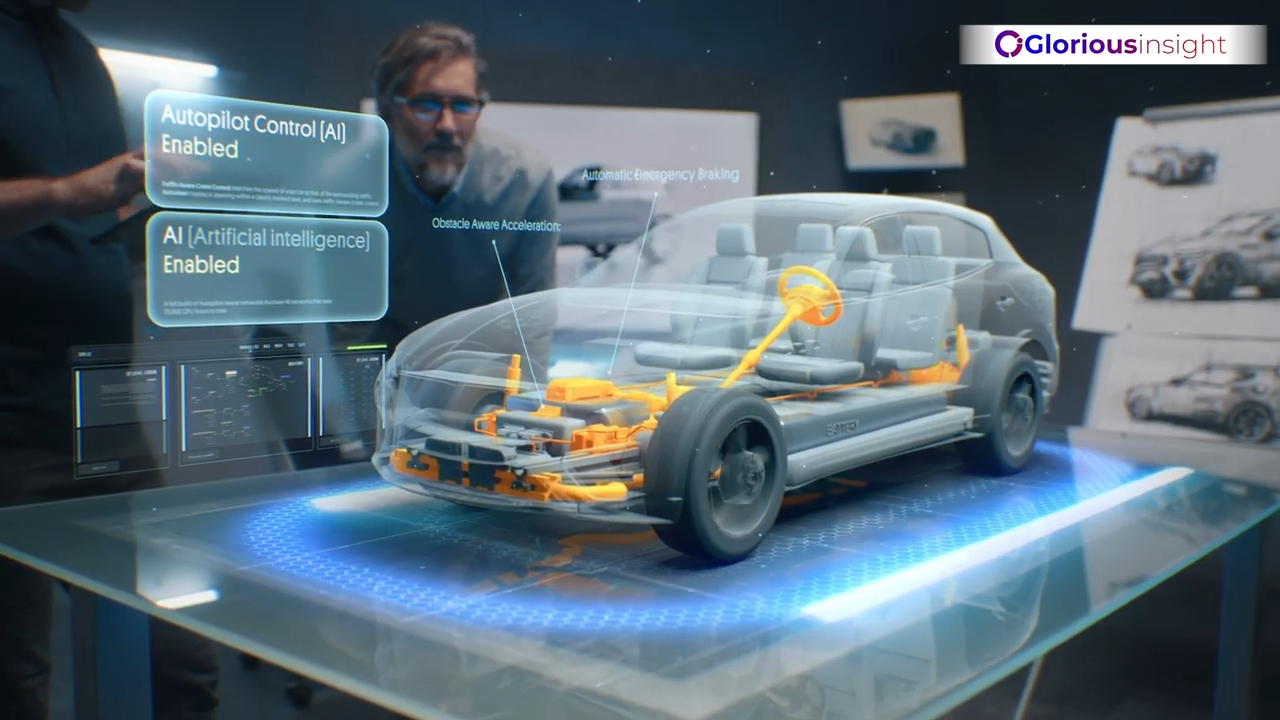

Autonomous driving advancements

Self-driving vehicles utilize AI algorithms to interpret their environment by evaluating data from cameras and sensors. This adaptability enables AI to make instant driving decisions, such as staying within lanes and avoiding collisions. Additionally, AI can conduct predictive analytics, helping autonomous vehicles prepare for possible dangers, traffic movement, and road conditions. All these can lower the risk of accidents, enhance traffic efficiency, and introduce innovative mobility options.

-

Predictive maintenance

Sudden breakdowns eat into time and money. AI can prevent these by studying sensor data from the vehicle. This contains crucial values, including engine efficiency and degradation of parts because of regular use. Algorithms can spot patterns and irregularities, letting AI foresee possible problems. It can then suggest scheduled maintenance, minimizing delays and preventing machine failure that's expensive to fix. This gives auto owners peace of mind and a stress-free experience, increasing customer satisfaction.

-

Smart infotainment systems

AI has personalized the driving experience with infotainment systems that learn and adapt to the preferences of drivers and passengers. This boosts overall comfort and enjoyment of the journey. Since these systems comprehend and respond to voice prompts, drivers can manage controls without removing their hands from the wheel. AI can study traffic patterns and weather updates, recommending alternative routes for a faster and safer drive.

-

Tracking inventory and streamlining supply chains

AI predicts demand by examining past data, market patterns and other parameters. This method guarantees timely inventory management and lowers expenses linked with surplus or insufficient inventory.

It can also optimize the supply chain by scheduling routes, managing the warehouse, and improving supplier coordination. Machine learning can study real-time data like traffic, fuel costs, and vendor performance to improve shipping and distribution processes. This results in smoother supply chain operations, maximizing capital while minimizing late deliveries.

-

Improved safety and security

Researchers are working to develop robust AI equipped to handle emergencies and, ultimately, save lives. AI is also an essential part of cybersecurity as autonomous vehicles become more connected.

In automotive manufacturing, this technology can strengthen quality control, guaranteeing the absence of defective parts that may compromise driver safety. AI-driven robots can accomplish routine and risky tasks to protect human workers. It can also monitor the workspace for safety hazards, enabling quick intervention to prevent accidents.

-

Enhanced vision technology services

Vision technology through cameras, sensors, and Light Detection and Ranging (LiDAR) is vital in autonomous vehicles. Even in manufacturing, the industry gains from Internet of Things (IoT) sensors along the production process to ensure quality control.

According to this report, 56% of automotive key players in the UK and over 40% in Germany stated they now use AI in their machine vision endeavors. This is because deep-learning machine vision provides unprecedented quality and precision, which is useful in more intricate processes, such as semiconductor production and EV battery manufacturing.

-

More affordable and faster simulation

Vehicles must fulfill stringent standards, such as safety, durability, and energy consumption. Up until the 1990s, researchers depended on concrete prototypes and testing processes. When Computer-Aided Engineering and Design (CAE & CAD) came into the picture, the testing cycles were shortened, lowering costs. But with the advent of AI, prototypes can be tested in various conditions through virtual simulation, eliminating the need for physical tests on actual roads.

-

Generative Design

AI can come even earlier in manufacturing, producing thousands of designs. For instance, if automakers want to produce a passenger car optimized for airflow, they can use a machine learning model trained in current car designs to generate new schematics.

Using AI in the initial stages of manufacturing can have a positive impact down the line. Concepts can be clearly explained during C-level meetings, creating a deeper discussion. Even in the design stage, stakeholders can identify potential issues and possible solutions, increasing the likelihood of developing an excellent product.

-

Excellent auto performance

With AI-based prediction, carmakers can generate aerodynamic shapes and functionalities that lower drag or resistance to motion, resulting in less energy consumption. Meanwhile, a design that boosts downforce increases traction and stability, especially in navigating turns. Because airflow can produce noise, a design that minimizes internal and external noise can increase passenger comfort.

-

Efficient knowledge transfer

AI can gather data and knowledge from veteran workers, manuals and other sources, summarizing them into digital formats that can be shared and easily accessed. Interactive and personalized learning methods are available for employees needing practical training. Furthermore, AI can promote knowledge sharing within the workforce by suggesting relevant literature, linking them with experts, and fostering collaboration in problem-solving projects.

As one of the Top 20 EMS companies in the world, IMI has over 40 years of experience in providing electronics manufacturing and technology solutions.

We are ready to support your business on a global scale.

Our proven technical expertise, worldwide reach, and vast experience in high-growth and emerging markets make us the ideal global manufacturing solutions partner.

Let's work together to build our future today.

Other Blog